AI-Powered Pollination Robots: The Future of Smart Agriculture

AI-Powered Pollination Robots: The Future of Smart Agriculture

AI-Powered Pollination Robots: The Future of Smart Agriculture

By Ronen Kolton Yehuda (Messiah King RKY)

As pollinator populations — including bees and other insects — continue to decline due to climate change, pesticides, and habitat loss, the agricultural sector is facing a major challenge: how to ensure successful crop pollination in the future.

The answer may lie in technology. Artificial Intelligence (AI)-powered pollination robots are emerging as a groundbreaking solution, offering precision, autonomy, and resilience in pollinating plants, trees, and crops without relying on natural pollinators.

What Are Pollination Robots?

Pollination robots are autonomous or semi-autonomous machines designed to perform the delicate task of transferring pollen between flowers. These machines can range from small aerial drones to ground-based robotic arms, each equipped with sensors, cameras, and AI algorithms that detect flowering plants and simulate the behavior of bees.

How AI Enhances Robotic Pollination

AI allows these robots to:

Identify flower types and maturity

Using image recognition and deep learning, robots detect which flowers are ready for pollination and which are not.

Navigate fields efficiently

AI-powered pathfinding enables robots to cover large areas with minimal energy use and no overlap.

Perform gentle and effective pollination

Robotic “brushes” or air pulses simulate bee movements, ensuring pollen is transferred accurately.

Adapt to conditions in real time

With environmental sensors and real-time data processing, robots can change behavior based on weather, humidity, or crop density.

Advantages Over Traditional Methods

Independence from natural pollinators

24/7 operation

Consistency and accuracy

No risk of stings or allergen exposure

Integration with smart farms and precision agriculture

Applications in Agriculture

Greenhouses and vertical farms

Open-field fruit and vegetable farms

High-value crops like almonds, strawberries, and tomatoes

Pollination during off-seasons or in harsh climates

Future Outlook

With ongoing research and investment, AI pollination robots could become standard tools in global agriculture. Their use will not only address the pollinator crisis but also usher in a new era of smart, sustainable, and climate-resilient farming.

AI-Powered Autonomous Pollination Systems: Technical Overview for Agricultural Integration

By Ronen Kolton Yehuda (Messiah King RKY)

Abstract

This paper outlines the design, functionality, and integration of autonomous robotic systems for artificial pollination in agricultural environments. Leveraging machine vision, environmental sensors, and AI algorithms, these robots are engineered to detect, classify, and pollinate flowering crops with high precision. The system aims to mitigate the global decline in pollinators and support high-efficiency farming under varying climate and ecological conditions.

1. Introduction

Global agriculture depends heavily on natural pollinators, particularly bees. With population collapses due to habitat destruction, pesticide use, and disease, the need for a technological replacement is urgent. AI-powered robotic pollinators are emerging as scalable, modular, and programmable alternatives that operate independently of biological limitations.

2. System Architecture

2.1 Robotic Hardware

Chassis Types: Aerial (drone-based), ground-based (wheeled or tracked), or hybrid VTOL systems.

End Effectors: Pollination brushes, soft actuators, air-pulse sprayers, or electrostatic arms to mimic pollen transfer.

Power Supply: Rechargeable batteries, solar panels, or tethered systems depending on scale and mobility.

2.2 Sensor Array

Multispectral Cameras: For flower recognition and phenological analysis.

LIDAR / Time-of-Flight Sensors: For 3D plant mapping and obstacle avoidance.

Environmental Sensors: Temperature, humidity, light levels, wind speed, and CO₂ concentration.

Pollen Detection Modules: Optional electrochemical or optical sensors to detect pollen presence or density.

3. Artificial Intelligence and Machine Learning Modules

3.1 Flower Detection and Classification

Convolutional Neural Networks (CNNs) trained on large agricultural datasets to recognize flower species, blooming stage, and health status.

3.2 Pollination Algorithm

Adaptive behavioral algorithms determine:

When and how to pollinate based on real-time flower status.

Optimal pollen collection and deposition sequences.

Time-based scheduling and route optimization.

3.3 Navigation and Autonomy

SLAM (Simultaneous Localization and Mapping) for real-time navigation.

Reinforcement Learning for optimization under uncertain conditions.

GPS or beacon-based pathing in open fields or controlled environments.

4. Communication and Data Logging

Wireless Connectivity: 5G/LTE/Wi-Fi modules enable real-time command and telemetry.

Data Logging: Crop pollination maps, flowering density, pollen dispersion analytics.

Integration: Compatible with smart farm platforms (IoT, Farm Management Systems).

5. Operational Workflow

Field Scanning

Robot begins mapping crop rows and flower locations using AI and vision systems.

Target Recognition

Filters flowers by maturity and necessity for pollination.

Pollination Execution

Using end-effector tools, it applies pollen with gentle contact or air dispersal.

Optimization Loop

Machine learning refines patterns daily, adjusting to crop variety and seasonal changes.

6. Use Case Applications

Greenhouses: Controlled environment pollination with minimal resource waste.

Fruit Orchards: Almonds, cherries, apples with tree canopy navigation.

Vertical Farms: Compact, modular pollination cycles in multi-layered systems.

Field Crops: Tomatoes, melons, cucumbers, and other precision-pollinated vegetables.

7. Limitations and Challenges

High cost of initial deployment

Need for species-specific training data

Weather-based performance constraints (for aerial drones)

Power management in remote areas

8. Future Development

Integration with robotic crop pickers and AI pesticide sprayers

Swarm-based AI coordination for large-scale farms

Pollination efficiency modeling and improvement via digital twins

Biodegradable or solar-powered versions for sustainability

9. Conclusion

AI-powered robotic pollinators offer a high-potential solution to global pollination challenges. With robust machine vision, adaptive algorithms, and modular design, these systems represent the next generation of precision agriculture and smart ecological engineering.

Here is a realistic product-focused technical article about supersmall AI-powered micro pollination robots, including engineering features, use cases, and deployment strategy:

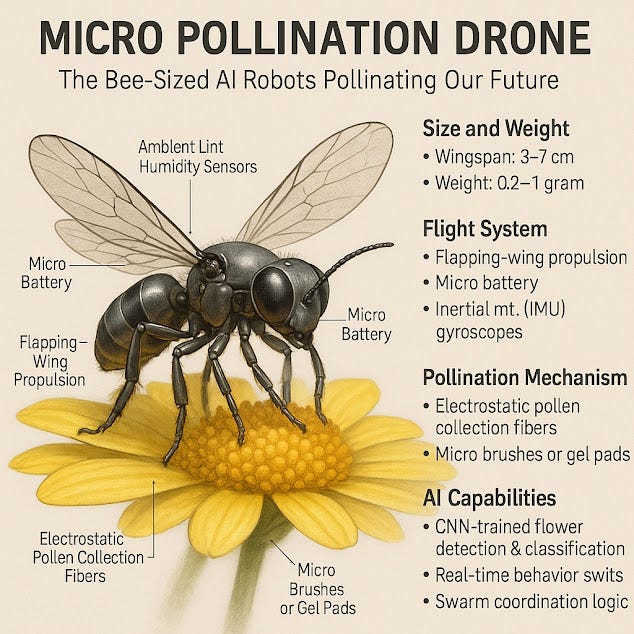

Micro Pollination Drones: The Bee-Sized AI Robots Pollinating Our Future

By Ronen Kolton Yehuda (Messiah King RKY)

As bee populations decline and crop pollination becomes a global agricultural concern, a new frontier in agritech has emerged: supersmall aerial AI robots designed to replicate the delicate and essential work of bees. These micro-scale flying pollinators, often the size of an insect, use artificial intelligence and precision engineering to deliver targeted pollination where natural pollinators can no longer reach.

Overview of the Micro Pollination Robot

These insect-sized flying robots combine advanced mechatronics, AI-driven perception, and ultralight propulsion systems to perform autonomous flower-to-flower pollination in open fields, greenhouses, and urban vertical farms.

Technical Specifications

1. Size and Weight:

Wingspan: 3–7 cm

Weight: 0.2–1 gram

Body: Carbon fiber or lightweight polymers with flexible wing joints

2. Flight System:

Type: Flapping-wing or micro quadcopter propulsion

Power: Micro-batteries with solar recharge or wireless inductive charging

Stabilization: Real-time inertial measurement unit (IMU) + mini gyroscopes

Navigation: Optical flow + beacon-based indoor tracking or GPS for outdoor

3. Pollination Mechanism:

Electrostatic Pollen Collection: Mimics bee hairs using charged nano-fibers

Micro Brushes or Gel Pads: Collects and releases pollen mechanically

AI-Controlled Actuators: Adjust approach angle and pollen contact pressure

4. AI Capabilities:

CNN-trained flower detection and classification

Real-time behavior switching based on flower maturity

Swarm coordination logic for large-area deployment

Adaptive scheduling based on temperature and humidity data

5. Sensors and Components:

Micro camera (down to 1mm wide)

Ambient light and humidity sensors

CO₂ concentration detector (optional)

Ultrasonic range finder for flower proximity

Field Use Cases

A. Precision Pollination in Greenhouses

Ideal for tomatoes, cucumbers, and strawberries

Replaces or supplements bumblebee colonies

Operates in artificial lighting and confined airflows

B. Tree Crop Pollination in Orchards

Almonds, apples, cherries

Deployable in swarms during peak bloom windows

Operates in early mornings or evenings when bees are inactive

C. Vertical and Indoor Farming

Compact farms in urban spaces with controlled climates

Operates on fixed light cycles and can cover multiple layers

Swarm Deployment Model

Robots are deployed from mobile base stations or wall-mounted hives

Central AI assigns coverage zones and recharging rotations

Real-time mapping creates flower density heatmaps

Faulty units automatically return or self-deactivate

Advantages

Independent of bee population cycles

Operates under extreme or non-natural conditions

No allergic risk, no hive maintenance, no stinging

Light enough to avoid damage to delicate flowers

Real-time analytics and cloud monitoring

Challenges

Power-to-weight ratio limits battery life (10–30 minutes per flight)

Precision manufacturing increases cost per unit

Environmental exposure (wind, rain) affects outdoor reliability

Ethical and ecological questions regarding mass deployment

Conclusion

Micro pollination robots represent the most biologically accurate and technologically advanced solution to the global pollinator crisis. With lifelike design, real-time AI adaptation, and swarm-based autonomy, these tiny flying machines may soon become vital companions in sustainable agriculture — not to replace nature, but to support it where it is failing.

Rescue and Repair Pollination Robots: The Next Generation of Autonomous Agricultural Swarms

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction: Beyond Pollination

As AI-powered pollination robots take on an increasingly vital role in smart agriculture, the need for maintenance, repair, and operational uptime becomes critical. A broken robot in a swarm can reduce pollination coverage, damage crops, or disrupt scheduling. To address this, a new class of support units is emerging: rescue and repair pollination robots — machines not only designed to pollinate, but also to identify, assist, retrieve, or repair fellow robots in the field.

Concept Overview

Rescue and Repair Pollination Robots (RRPRs) are specialized autonomous systems integrated into robotic pollination fleets. Their purpose is to detect faulty or stalled pollinators, assess their condition, and either repair them on-site or carry them back to a central charging or maintenance station.

Key Capabilities

1. Fault Detection & Identification

RRPRs constantly scan their environment for signals or behavior indicating malfunction:

No movement for a set period

Abnormal heat signatures or battery output

Self-diagnostic error pings sent wirelessly by failing units

2. On-Site Repair Tools

Equipped with modular toolkits and robotic arms, RRPRs can:

Replace or reset pollination end-effectors (brush, gel pad, static wand)

Perform minor wiring or sensor reboots

Recharge microbots with portable energy cells or wireless energy transfer

3. Transport & Retrieval

If repair is not feasible on-site, RRPRs have mechanical lifting or docking capabilities:

Micro-grippers or magnetic docking ports for small drones

Wheeled platforms with slots to hold and stabilize malfunctioning bots

Short-range vertical takeoff (mini-VTOL) for emergency lift of aerial drones

AI and Sensor Systems

AI Diagnostics Engine: Interprets fault codes, prioritizes response, and allocates tasks across RRPRs

Robot Recognition System: Uses visual ID tags or beacon frequencies to identify broken units

Thermal & EM Scanners: Detects overheating or EM interference indicative of failure

Multi-Agent Coordination AI: Ensures that RRPRs do not interfere with active pollinators and optimize repair routes

Use Case Scenarios

1. Greenhouses & Vertical Farms

RRPRs operate on rails or wheels within tight spaces

Capable of replacing modules in mounted systems without shutting down operations

2. Orchards and Fields

RRPRs work with drone pollinators, retrieving fallen units or intercepting failing units mid-air

Swarm-based patrols cover wide open areas using coordinated GPS and LIDAR maps

3. Swarm Recovery Management

RRPRs log every recovery and synchronize data with central farm systems

AI tracks failure patterns and predicts maintenance needs, reducing downtime

Advantages

Uptime Maximization: Keeps pollination operations running with minimal interruption

Self-Maintaining Ecosystem: Reduces need for human technicians in the field

Reduced Operational Cost: Prevents loss or damage of units through timely intervention

Adaptive Redundancy: Swarm intelligence ensures new RRPRs are dispatched dynamically

Future Developments

Autonomous Maintenance Hubs: Mobile stations staffed by RRPRs for localized repair

AI Co-learning Systems: Fault data shared with pollinators to improve design and prevention

Drone-to-Drone Repair: Advanced micro-robots capable of air-based repairs during mission

Conclusion

The rise of pollination robots calls for a parallel development in robot support infrastructure. Rescue and repair units are the keystone of a self-sustaining robotic ecosystem, ensuring uninterrupted agricultural productivity and long-term scalability. In the fields of tomorrow, not only will robots pollinate — they will heal one another, learn from failures, and ensure resilience in the face of adversity.

🛰️ Version 1: Rescue-Only Pollination Robots

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction: A Lifeline for Smart Farms

As robotic pollinators become essential tools in precision agriculture, ensuring their operational continuity is critical. But what happens when one fails mid-task? To maintain uninterrupted pollination, farms are now deploying rescue-only units: specialized robots designed to detect and retrieve malfunctioning pollinator robots quickly and safely.

What Is a Rescue Pollination Robot?

A rescue pollination robot is not designed to pollinate. Instead, it works like an autonomous ambulance — navigating the farm to locate, collect, and transport nonfunctional or stuck robots back to a service base.

Key Capabilities

1. Autonomous Search & Detection

Uses swarm tracking systems and GPS logs to identify missing or inactive pollinators

Can detect abnormal heat signatures or emergency signals from broken units

2. Pickup & Transport

Equipped with micro-grippers, magnetic clamps, or soft docking bays

Can safely carry small drones or wheeled pollinators without damage

3. Central Communication Sync

Works with the farm’s AI system to log retrievals

Notifies maintenance staff or automated repair stations of incoming units

Deployment Examples

In orchards, drones that crash or lose power are retrieved before weather damage or animal interference occurs

In greenhouses, units stranded on tracks or jammed between plants are recovered by rail-based rescue bots

In vertical farms, rescue bots retrieve stuck microbots from multiple layers

Advantages

Prevents downtime across pollination operations

Minimizes risk of damage to delicate robotic equipment

Supports fully autonomous pollination systems by closing the failure-response gap

Conclusion

Rescue-only pollination robots are an essential layer of redundancy in the evolving smart farming ecosystem. They ensure that even when technology stumbles, the system as a whole keeps growing — quite literally.

🔧 Version 2: Rescue and Repair Pollination Robots

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction: Self-Sustaining Robotic Ecosystems

The future of agriculture depends not only on robots that can pollinate — but on those that can support each other. Rescue-and-repair pollination robots represent the next evolution in agricultural autonomy: machines capable of locating, assisting, and even fixing malfunctioning pollinator units without human intervention.

What Are Rescue & Repair Pollination Robots?

These specialized support bots are designed to search for failed pollinators, diagnose the issue, and either repair them on the spot or carry them to a maintenance hub.

Core Features

1. Failure Detection System

Monitors the health of swarm units in real time

Detects communication loss, immobility, overheating, or error codes

2. On-Site Repair Capabilities

Modular tool arms with replaceable end-effectors (brush heads, wiring kits)

Recharge capability via docking or portable battery cell

Sensor recalibration and soft reboot protocols

3. Autonomous Transport

Wheeled platform, drone, or VTOL-based mobility

Carries broken units to service stations if repair fails

4. AI Coordination

Connected to the swarm AI

Assigns priority to breakdowns based on pollination timing and crop criticality

Use Scenarios

High-tech smart farms with minimal labor

Remote greenhouses where tech teams are unavailable

Disaster-prone areas needing resilient, self-sufficient operations

Benefits

Reduces need for manual field inspection

Ensures continuous operation across critical growth phases

Saves cost over time by extending robot lifespan and avoiding cascade failures

Conclusion

Rescue and repair units turn a pollination fleet into a self-reliant organism — capable of adapting, recovering, and repairing itself. These support robots are not just tools — they are guardians of the farm, ensuring that every flower gets its chance to bloom.

Rescue and Repair Pollination Robots: A Technical Architecture for Autonomous Maintenance in Agricultural Robotics

By Ronen Kolton Yehuda (Messiah King RKY)

Abstract

As AI-powered pollination robots become integral to modern agriculture, maintaining their operational uptime is essential. This paper introduces the concept of Rescue and Repair Pollination Robots (RRPRs) — autonomous service units designed to locate, diagnose, and either repair or retrieve malfunctioning pollinator robots. The system combines multi-sensor diagnostics, modular repair tools, and AI-based coordination for fully autonomous maintenance in smart farming environments.

1. System Overview

1.1 Purpose

To autonomously ensure continuity of pollination operations by:

Detecting inoperative or malfunctioning robots in the field

Performing minor repairs or transporting them to maintenance zones

Operating as part of a coordinated robotic swarm

2. Mechanical Architecture

Subsystem Description

Chassis Wheeled (4WD or tracked) or VTOL drone base, weather-resistant

Manipulator Arm 4-DOF (Degrees of Freedom) robotic arm with interchangeable tool head

Docking Bay Secure platform for carrying disabled microbots or drone pollinators

Power Supply Lithium-ion battery, solar augmentation (optional), auto-dock recharge

Redundant Actuators Ensures stability under load or rough terrain retrieval

3. Sensor Suite and Diagnostics

Sensor Type Function

Thermal Imaging Camera Detects overheating or stalled motors

EM Interference Detector Identifies signal faults or short circuits

LIDAR / Time-of-Flight 3D mapping and obstacle avoidance

RF Signal Tracker Locates distress beacons or signal-loss patterns from swarm members

Machine Health Interface (MHI) Reads diagnostic data from peer robots via NFC or BLE

4. Repair Toolkit and Capabilities

Tool / Module Function

Soft-tip Manipulator For gentle reset of sensors or connectors

Micro-Welding Unit For emergency wire reconnection or joint repair

End-Effector Replacement Tray Carries spare brushes, gel tips, or pollen pads

Recharge Module Provides emergency power via contact pads or wireless coil

Sensor Calibrator Re-aligns LIDAR or camera heads on stalled units

5. AI Architecture

5.1 Fault Detection & Prioritization

Uses predictive analytics on pollination logs

Combines swarm telemetry, power loss patterns, and anomaly detection

Prioritizes recovery based on:

Pollination schedule urgency

Robot importance in local cluster

Distance and repairability

5.2 Navigation and Task Execution

SLAM + GPS Hybrid Navigation for locating units in open or structured spaces

Path Planning Engine ensures shortest path with minimal impact on active pollinators

Behavior Tree AI enables condition-based switching between rescue, repair, and recharge operations

6. Operational Workflow

Monitoring: Continuously analyzes data streams from all robots

Fault Detection: Identifies inactive or malfunctioning units using AI

Dispatch: Nearest RRPR receives task parameters and location

Assessment: Performs physical inspection or NFC handshake diagnostics

Decision:

If repairable: executes repair on-site

If not: docks and transports unit to recharge/repair station

Return to Base: Syncs logs and charges

7. Deployment Scenarios

Environment RRPR Variant Advantages

Greenhouses Rail-based RRPR High precision, integrates with control systems

Orchards Wheeled or aerial RRPR Flexible terrain access, rapid response

Vertical Farms Modular drone RRPR Layer-by-layer coverage, zero disruption

Outdoor Fields All-terrain ground RRPR Dust/weather resistance, long endurance

8. System Benefits

Uptime Assurance: Minimizes downtime of pollination fleets

Labor-Free Recovery: Fully autonomous support system

Scalable Design: One RRPR can support dozens of units per zone

Extended Robot Lifespan: Reduces wear-and-tear escalation through early intervention

9. Future Enhancements

Self-Healing Swarms: Shared AI learning to prevent repeated faults

Predictive Failure AI: Based on environmental and operational history

Bio-Hybrid RRPRs: Lightweight, bee-sized versions for micro-swarms

Maintenance Drone Hive Stations: Auto-repair facilities for large-scale farms

Conclusion

The integration of Rescue and Repair Pollination Robots ensures resilient, autonomous, and scalable farming operations. These support units represent a critical infrastructure layer in AI-driven agriculture — transforming robotic fleets from dependent machines into self-sustaining ecosystems.

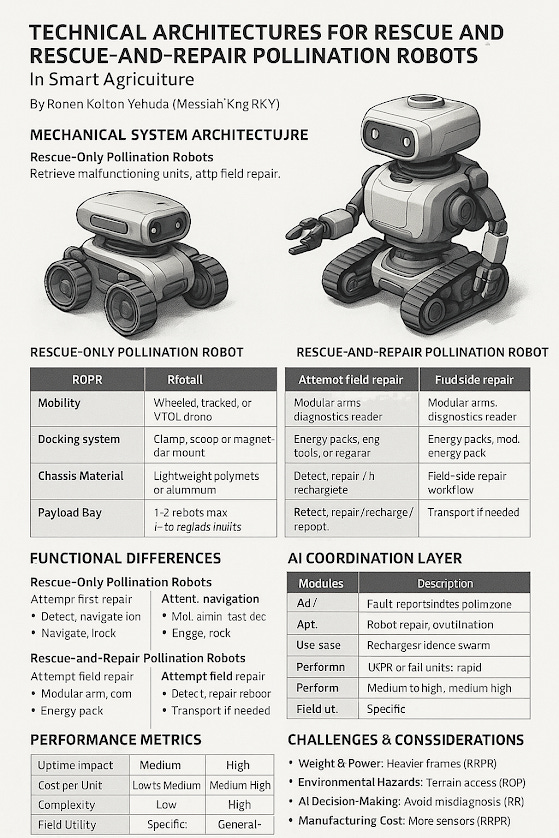

Technical Architectures for Rescue and Rescue-and-Repair Pollination Robots in Smart Agriculture

By Ronen Kolton Yehuda (Messiah King RKY)

Abstract

As pollination robotics expands into mainstream agriculture, the resilience of robotic fleets becomes critical. This paper outlines two specialized classes of support units: Rescue-Only Pollination Robots (ROPRs) and Rescue-and-Repair Pollination Robots (RRPRs). These systems serve to autonomously recover or maintain malfunctioning pollination units within greenhouses, orchards, vertical farms, and open fields. We present their mechanical, sensory, and AI architectures, highlighting operational workflows and use-case distinctions.

1. Introduction

Pollination robots perform critical tasks across global agricultural sectors, especially as natural pollinators decline. However, their uptime is vulnerable to mechanical failures, sensor drift, power loss, or environmental disturbances. To maintain continuity, farms are now deploying dedicated support units designed for:

Retrieval only (ROPRs)

Retrieval and autonomous on-site repair (RRPRs)

2. Mechanical System Architecture

Component Rescue-Only Robot (ROPR) Rescue-and-Repair Robot (RRPR)

Mobility Wheeled, tracked, or VTOL drone Wheeled or hybrid VTOL with heavier load capacity

Docking System Clamp, scoop, or magnetic mount Same, plus shock-absorbing cargo stabilization

Chassis Material Lightweight polymers or aluminum Reinforced alloy, shock-resistant frame

Payload Bay For retrieval only (1–2 robots max) Includes storage for tools, parts, and charging kits

3. Sensor Suite

Sensor Type Functionality in Both ROPR & RRPR

Thermal IR Camera Detects overheating in failed robots

Multiband Beacon Scanner Locates units emitting distress signals or failure pings

LIDAR / SLAM Mapping Real-time navigation in greenhouse and outdoor terrain

UWB / BLE Tracker Pinpoint location of pollinators via unique robot ID signatures

IMU / Tilt Sensor Verifies if pollinator unit is tipped, jammed, or obstructed

4. Functional Differences

4.1 ROPR – Rescue-Only Pollination Robots

Purpose: Retrieval and safe transport of failed or stalled pollination robots

Key Characteristics:

No repair capability

Lightweight design for fast navigation

Focus on speed and field coverage

Workflow:

Detect failed unit via GPS log or emergency beacon

Navigate to site

Engage docking mechanism

Transport back to maintenance base

4.2 RRPR – Rescue-and-Repair Pollination Robots

Purpose: Rescue with optional field-side repair or reactivation

Key Characteristics:

Modular arm with end-effector tool switching

Internal diagnostics reader for peer-to-peer robot interface

Portable energy pack or wireless charging pad

AI-driven fault prioritization and repair sequencing

Repair Toolkit Includes:

Spare soft brushes, gel pads, pollen cartridges

Wire reconnectors or solderless clips

Sensor calibration laser for IR/UV lens alignment

Reboot protocols with NFC/BLE handshake

Workflow:

Detect and assess status of failed robot

If repairable: perform field fix, recharge or reboot

If irreparable: transport back to maintenance station

Log all actions and performance metadata

5. AI Coordination Layer

Module Description

Fault Prioritization AI Evaluates importance based on time-critical pollination zones

Pathfinding Engine Avoids live pollinators and optimizes energy-efficient routes

Repair Decision Tree Diagnoses errors (hardware vs software) and selects action

Swarm Management Sync Updates fleet about restored units and operational changes

6. Use Case Deployment

Scenario Recommended Robot Type Reason

Greenhouses (high density) RRPR or rail-mounted units Confined space; quick repairs prevent cascading failure

Orchards (open terrain) ROPR + RRPR mix Wide range; some failures may require back-to-base retrieval

Vertical farms Micro ROPRs or RRPR drones Layered structure; must dock and climb with payloads

Autonomous Smart Farms Full RRPR fleet Minimal labor; fully robotic farm environments

7. Performance Metrics

Metric ROPR RRPR

Uptime Impact Medium (recovery only) High (recovery + repair)

Cost per Unit Low to Medium Medium to High

Complexity Low High

Field Utility Specific General-purpose

8. Challenges and Considerations

Weight & Power: RRPRs require heavier frames and more energy for manipulation and diagnostics

Environmental Hazards: ROPRs may not be able to retrieve units from rough or wet terrain

AI Decision-Making: RRPRs must avoid misdiagnosis that could cause further damage

Manufacturing Cost: RRPRs have more sensors and mechanical subsystems, increasing cost per unit

9. Conclusion

Both ROPRs and RRPRs are integral to the future of autonomous agricultural systems. ROPRs provide a cost-effective first response for pollination fleet recovery, while RRPRs offer a more complete and self-sustaining solution — essential for remote or fully autonomous farms. Their integration into smart agriculture ensures continuous productivity, system resilience, and reduced reliance on human intervention.

Can Robots Save Our Crops? The Rise of AI-Powered Pollination in Agriculture

By Ronen Kolton Yehuda (Messiah King RKY)

As bees and other natural pollinators disappear at an alarming rate, farmers around the world are facing a new and urgent question: who — or what — will pollinate our crops in the future?

The answer may not be found in nature, but in technology. Scientists and engineers are now building AI-powered pollination robots — futuristic machines that can take on the role of bees, flying or moving through fields to pollinate plants, flowers, fruits, and vegetables.

Why Are Pollinators Disappearing?

In recent decades, pollinators like bees, butterflies, and birds have declined due to:

Pesticides

Climate change

Habitat destruction

Disease and pollution

Since about 75% of our food crops rely on pollination, this crisis affects not only biodiversity, but also global food supply and prices.

What Are AI Pollination Robots?

Pollination robots are machines equipped with artificial intelligence, cameras, sensors, and special tools that allow them to:

Identify flowers that are ready for pollination

Navigate through greenhouses or farms

Transfer pollen gently, like bees do

Work in all conditions — even at night or in bad weather

Some of these robots look like flying drones. Others are small rovers that drive between rows of plants. In both cases, their mission is the same: keep crops growing, even if natural pollinators vanish.

How Do They Work?

Using smart cameras and AI, these robots can:

Recognize different plants and flowers

Decide which ones need pollination

Use soft brushes, air puffs, or static charges to move pollen

Learn and improve over time with data

Some even work in swarms — many robots working together to cover large areas quickly.

Where Are They Being Used?

AI pollination robots are already being tested or used in:

Greenhouses for tomatoes, cucumbers, and strawberries

Fruit orchards like almonds and apples

Vertical farms in cities

Experimental smart farms using drones and IoT systems

Countries like Japan, Israel, the USA, and the Netherlands are leading the way.

Why This Matters

Food Security: Robots can ensure we still have fruits and vegetables even if bees disappear.

Climate Adaptation: Robots work in extreme climates and closed environments.

Year-Round Growing: With robots, pollination can happen outside traditional seasons.

Labor Shortage: In areas with few workers, robots help keep farms running.

Is This the End of Natural Pollination?

Not at all. These robots are not designed to replace nature — but to support it. In places where bees are thriving, we must protect and restore their habitats. But in places where pollinators are gone or struggling, technology may be the bridge that keeps farms alive.

The Future: Smart Farms and Robotic Ecosystems

In the coming years, we may see entire farms run by AI:

Robots pollinating

Drones planting and spraying

Sensors monitoring plant health

Smart irrigation systems using weather data

Together, these tools could create eco-friendly, efficient, and sustainable farms — feeding the world without harming the Earth.

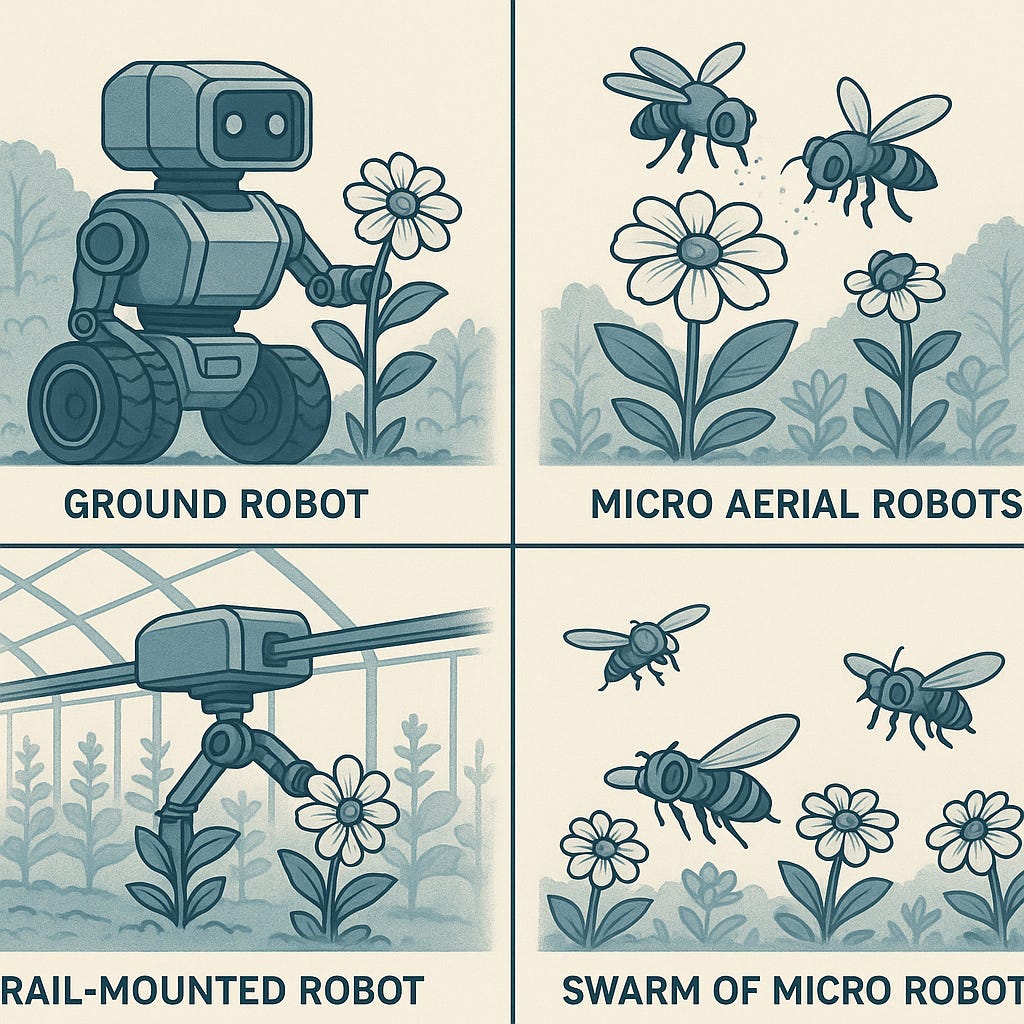

AI-Powered Pollination Robots: Multiple Solutions for the Future of Farming

By Ronen Kolton Yehuda (Messiah King RKY)

As traditional pollinators like bees decline, the agricultural sector must adapt. One of the most promising developments is the emergence of AI-powered pollination robots—intelligent machines capable of identifying flowers and transferring pollen with accuracy, independence, and speed. Several types of robotic pollinators are already being developed, each with unique strengths for specific environments and crops.

1. Aerial Drone Pollinators

Design: Small, lightweight quadcopters equipped with pollen dispensers, soft brushes, and high-resolution cameras.

Ideal For:

Orchards (almonds, cherries, apples)

Open fields of flowering vegetables

Large areas with scattered blooming zones

Advantages:

Covers large areas quickly

Works above the crop canopy

Minimal crop disturbance

2. Ground-Based Rover Pollinators

Design: Wheeled or tracked robots that navigate between rows of plants, equipped with robotic arms and soft contact tools.

Ideal For:

Strawberries, tomatoes, cucumbers

Greenhouses

Vineyards and berry farms

Advantages:

Precise flower targeting

Higher battery efficiency

Better integration with sensors and soil data

3. Greenhouse Rail Robots

Design: Ceiling-mounted or wall-mounted robotic arms that travel on fixed tracks inside controlled environments.

Ideal For:

Tomatoes, peppers, cucumbers in hydroponic greenhouses

Vertical farms

Advantages:

Consistent pollination in high-density areas

Fully integrated with greenhouse management systems

Operates continuously and autonomously

4. Swarm-Based Microbots

Design: Tiny coordinated robots working in groups to cover large areas or intricate plant geometries.

Ideal For:

Delicate flowers

Indoor farms

Experimental or sensitive crops

Advantages:

Scalability and redundancy

High adaptability to different flowers

Cooperative intelligence improves efficiency

5. Hybrid Pollination & Harvest Robots

Design: Multifunctional robots that switch between pollination and harvesting modes depending on the crop stage.

Ideal For:

Smart farms aiming for full-cycle automation

Tomatoes, melons, berries

Sustainable and autonomous farm models

Advantages:

Year-round utility

Cost-effective deployment

Reduces equipment footprint

Conclusion

AI-powered pollination robots are not a single solution, but a family of specialized systems—each addressing different needs of modern agriculture. Whether flying over almond orchards or rolling through rows of strawberries, these technologies represent the future of food security, environmental resilience, and smart farming.

As these systems evolve, they will not only pollinate our plants—but also collect data, learn from the environment, and cooperate with other machines. In doing so, they ensure a world where agriculture thrives—even in the absence of natural pollinators.

AI-Powered Pollination Robots: Technical Typologies and Deployment Scenarios in Agriculture

By Ronen Kolton Yehuda (Messiah King RKY)

Abstract

This technical review categorizes and compares the main architectures of artificial intelligence-powered robotic pollination systems currently developed for agricultural use. With global declines in natural pollinators and increasing demand for precision agriculture, these autonomous or semi-autonomous systems offer scalable alternatives across greenhouse, orchard, and field environments. The article classifies five main robotic designs—drone-based, ground rovers, rail systems, microbot swarms, and hybrid pollinator-harvesters—detailing their mechanical architecture, AI modules, sensor integration, and field applications.

1. Aerial Drone Pollinators

System Architecture

Platform: Multirotor UAVs (quadcopter or hexacopter)

Power: Rechargeable lithium batteries or solar-recharge base stations

Pollination Mechanism: Soft brush rotors, electrostatic dispensers, or compressed air puffers

Sensors & AI

Cameras: Multispectral and RGB for flower detection

Navigation: SLAM (Simultaneous Localization and Mapping) + GPS

AI Capabilities:

CNN-based flower maturity classification

Real-time flight path optimization via reinforcement learning

Adaptive altitude and proximity control based on plant topology

Use Case

Tree crops (almonds, apples, plums), wide-open flowering vegetable fields

2. Ground-Based Rover Pollinators

System Architecture

Chassis: Four- or six-wheel drive with adjustable ground clearance

End Effectors:

Articulated arms with pollen brushes

Electrostatic charge plates for pollen transfer

Sensors & AI

Vision: Stereo cameras with IR and ultraviolet capability

Sensors: LIDAR, ultrasonic, humidity, and CO₂ sensors

AI Modules:

Flower segmentation using edge detection and deep learning

Path optimization and non-redundant route mapping

Crop density-aware behavior switching

Use Case

Row crops like strawberries, cucumbers, or tomatoes in open fields and greenhouses

3. Greenhouse Rail-Mounted Pollinators

System Architecture

Mounting System: Ceiling or side-mounted linear rail with motorized carriage

Pollination Unit:

Programmable soft-brush contact unit or pollen sprayer

Swappable heads for different flower types

Sensors & AI

Imaging: High-resolution linear cameras synchronized with movement

AI Engine:

Real-time flower bloom detection

Pollination sequencing engine per crop type

Integration with greenhouse climate control systems (IoT)

Use Case

High-density hydroponic greenhouses (tomatoes, bell peppers)

4. Swarm-Based Micro-Pollinators

System Architecture

Form Factor: Miniaturized wheeled or hovering microbots

Communication: Mesh network with decentralized control

Pollination Tools: Micro-sprayers or nano-brushes

Sensors & AI

Positioning: Beacon triangulation or UWB positioning

AI Framework:

Multi-agent coordination through swarm intelligence

Task distribution based on flowering density heatmaps

Real-time feedback loops for adaptive pollination intensity

Use Case

Delicate crops, indoor farms, or layered vertical farming environments

5. Hybrid Pollinator-Harvest Robots

System Architecture

Body: Modular robot with interchangeable tools for harvesting and pollination

Pollination Module: Static brushes or pollen cartridge systems

Harvesting Module: Soft robotic grippers with ripeness sensors

Sensors & AI

Integrated Vision: Combines ripeness detection and floral stage analysis

AI Integration:

Task switching logic based on time-of-day or plant growth stage

Shared data bus for learning across modules

Cloud-connected for yield forecasting and pollination logs

Use Case

Precision smart farms seeking full-cycle automation

Comparison Table

TypeBest Use EnvironmentPrecisionArea CoverageScalabilityCostDrone PollinatorsOrchards, large fieldsMediumVery HighHighMediumGround Rover PollinatorsRow crops, greenhousesHighMediumMediumMediumRail-Mounted PollinatorsGreenhouses, vertical farmsVery HighLowLowLowMicrobot SwarmsVertical farms, sensitive cropsHighMediumVery HighHighHybrid Pollinator-HarvestersFull-cycle smart farmsHighMediumMediumHigh

Conclusion

AI-powered pollination robots provide a diverse set of technical solutions to the pollination crisis. By aligning specific robotic architectures with crop environments and growth cycles, farmers can deploy effective, sustainable, and autonomous pollination strategies. Continued advances in robotics, AI, and sensor fusion will make these systems more adaptive, affordable, and essential in the future of smart agriculture.

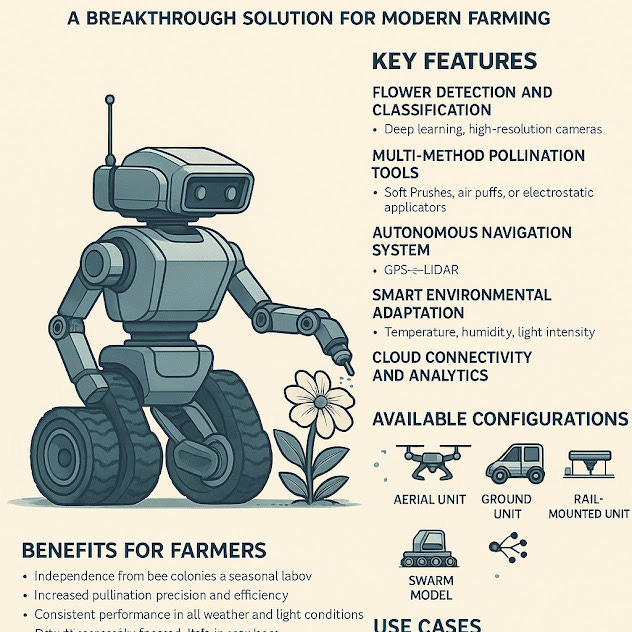

AI-Powered Pollination Robot: A Breakthrough Solution for Modern Farming

By Ronen Kolton Yehuda (Messiah King RKY)

As natural pollinators continue to decline due to climate change, pesticides, and habitat loss, farmers and agritech developers are turning to a new kind of worker: the autonomous, AI-powered pollination robot. This innovative machine combines advanced technology with biological insight to carry out one of the most critical tasks in agriculture — pollination.

Product Overview

The AI-powered pollination robot is a fully autonomous system that navigates farms, identifies flowering plants, and performs precision pollination. Whether deployed in greenhouses, orchards, or open fields, the robot ensures consistent, reliable pollination even in the absence of bees and other insects.

Key Features

1. Flower Detection and Classification

Using deep learning and high-resolution cameras, the robot identifies plant species, bloom stages, and flower health in real time.

2. Multi-Method Pollination Tools

Equipped with soft brushes, air puffs, or electrostatic applicators, the robot can transfer pollen accurately with no damage to the plant.

3. Autonomous Navigation System

With GPS, LIDAR, and obstacle-avoidance algorithms, it moves seamlessly through rows of crops or under tree canopies, optimizing coverage.

4. Smart Environmental Adaptation

Sensors monitor climate conditions like temperature, humidity, and light intensity. The robot uses this data to adjust its behavior and schedule.

5. Cloud Connectivity and Analytics

All operations are tracked and logged, offering farmers access to pollination heatmaps, flowering timelines, and productivity metrics.

Available Configurations

Aerial Unit: A flying drone version for use in orchards and open terrain.

Ground Unit: A wheeled rover for vegetables, vineyards, and greenhouses.

Rail-Mounted Unit: Designed for linear greenhouse setups or vertical farms.

Swarm Model: Multiple small robots working in coordinated networks to pollinate densely planted areas or fragile crops.

Benefits for Farmers

Independence from bee colonies and seasonal labor

Increased pollination precision and efficiency

Consistent performance in all weather and light conditions

Real-time monitoring and data integration

Supports sustainable and autonomous farming operations

Use Cases

Greenhouses growing tomatoes, cucumbers, or strawberries

Outdoor orchards with fruit trees such as apples or almonds

Smart farms and vertical agriculture systems

Research centers and precision agriculture facilities

Conclusion

The AI-powered pollination robot is more than a machine — it’s a reliable, intelligent partner in agriculture. It provides a scalable solution to the pollination crisis while enabling data-driven, efficient, and sustainable crop production. As farming moves into the future, such systems will become an essential part of resilient food production worldwide.

Legal Statement – Intellectual Property & Collaboration

This concept of “AI-Powered Pollination Robots” (covering autonomous aerial, ground, rail-mounted or swarm systems, and support/rescue/repair units) is an original creative and technical work authored by Ronen Kolton Yehuda (MKR: Messiah King RKY). All rights in the expression of the concept—including text, system architecture, functional modules, design notion, product lines, deployment scenarios, marketing vision and illustrations—are reserved by the author.

The author acknowledges that the field of robotic pollination already includes existing patents and published applications, for example:

US20160353661A1 – “Systems and methods for selective pollination” (robotic device with sensors, pollen delivery, collection and monitoring). Google Patents

US‑11470784‑B2 – Unmanned aerial vehicle for augmenting plant pollination. PubChem

Walmart Inc. patent applications for autonomous “robot bees”/pollination drones. Business Insider+1

CN115380817A – “Pollination robot” with crawler belt, mechanical arms and detection assemblies. Google Patents

By publishing this concept, the author does not claim to override or ignore those existing patents. Rather, this document is presented as an open-innovation proposal identifying potential collaboration, licensing or development opportunities under mutually agreed terms, provided that any commercialisation respects third-party rights.

Collaboration & Licensing Framework:

Interested parties (manufacturers, confectioners, agricultural technology firms, investors) are invited to engage with the author in good-faith discussions regarding:

Licensing of the concept, architecture, or specific modules;

Joint development or co-ownership of resulting products;

Modification of brand, naming, product positioning (as required by IP due-diligence).

Any commercial implementation originating from this concept must ensure:

A freedom-to-operate review or patent-clearance for relevant jurisdictions;

Appropriate attribution to the author (Ronen Kolton Yehuda (MKR: Messiah King RKY)) unless explicitly renegotiated;

A written agreement covering rights, revenue-sharing, responsibilities, and liability.

Where existing patents or patent applications cover overlapping technologies, the author is open to structuring arrangements such that:

Either the infringing scope is redesigned, or

A licensing deal is made with the third-party patent holder, or

The project proceeds under a new brand name or novel architecture that avoids conflicting claims.

The author retains the right to publish, present, or license the concept elsewhere, provided that such use does not conflict with any signed exclusivity agreement.

Disclaimer:

This publication is informational and conceptual in nature, aimed at fostering innovation, collaboration and sustainable agricultural development. It does not constitute a commercial offer, nor a guarantee of product viability, regulatory compliance, or patent-validity. Any party planning to manufacture, sell or invest in the technology outlined should conduct full legal, technical and commercial due diligence.

© 2025 Ronen Kolton Yehuda (MKR: Messiah King RKY) — All rights reserved.