Hybrid Robots: The Fusion of Manual Expertise and Autonomous Intelligence

Hybrid Robots: The Fusion of Manual Expertise and Autonomous Intelligence

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

Hybrid robots are revolutionizing the relationship between humans and machines.

By combining the skill and intuition of human operators with the power and efficiency of artificial intelligence, hybrid robotic systems are setting a new standard for precision, safety, and flexibility across industries.

What Defines a Hybrid Robot?

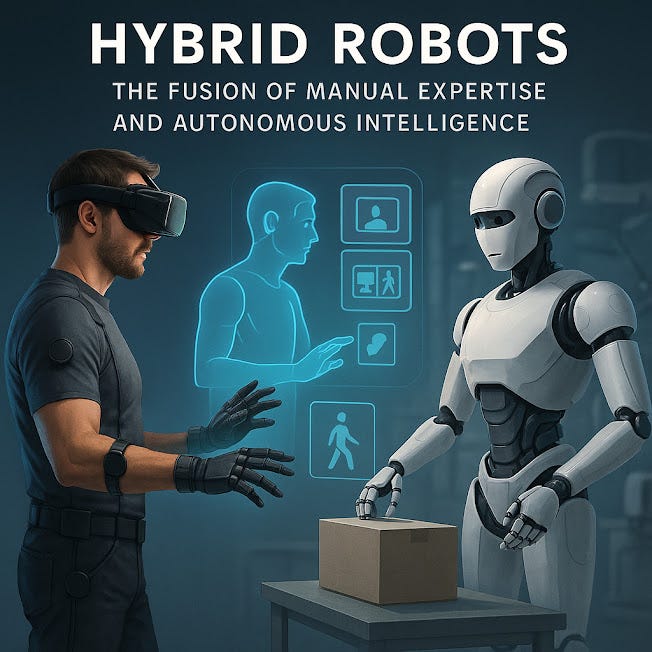

A hybrid robot can seamlessly shift between:

Manual control: A human operator directly guides the robot using VR/AR interfaces and wearable sensors.

Autonomous operation: The robot independently analyzes its environment and performs tasks based on AI-driven algorithms.

At any moment, control can transition fluidly between manual and autonomous modes, allowing for superior adaptability.

The Operating System

Wearable Gear:

Operators wear gloves, suits, or wristbands embedded with motion sensors, capturing physical actions.

VR/AR Control Interface:

Through glasses or headsets, operators see a digital avatar of themselves and a live 3D environment where robots act.

Digital Avatar Interface:

Operators issue commands manually through gestures or select pre-programmed tasks from a virtual panel.

Autonomous Intelligence:

The robot, equipped with AI, sensors, and machine learning capabilities, autonomously performs assigned tasks, navigates, and reacts to environmental changes.

Benefits of Hybrid Robots

Human-Intelligent Collaboration: Human finesse combined with robotic endurance creates unparalleled task performance.

Enhanced Safety: Dangerous or unreachable environments can be navigated with minimal human risk.

Flexible Control: Operators can shift from fine manual operations to broader autonomous tasks at any time.

Increased Productivity: Hybrid control reduces fatigue and multiplies efficiency, especially in manufacturing, logistics, and rescue missions.

Practical Applications

Warehouses and Factories:

Robots autonomously handle logistics but are manually directed for delicate tasks such as packaging custom items.

Disaster Zones:

Robots independently scan unstable environments, with operators taking control when sensitive or critical interventions are needed.

Space Missions:

Astronauts manually control robots for complex repairs, while autonomous systems conduct routine exploration or maintenance.

Healthcare:

Surgeons control robotic instruments during critical surgeries, while support robots autonomously manage surgical prep and monitoring.

The Future of Hybrid Robotics

The next generation of hybrid robots will:

Predict operator intentions through AI analysis.

Improve avatar realism with full-body haptic feedback.

Offer more intuitive and brain-connected control methods.

Enable collaborative missions between human teams and autonomous robot groups.

Hybrid robotics represents not just an improvement — but a transformation — in how humanity builds, explores, heals, and protects.

Remote Robot Operation with Wearable-Controlled Digital Avatar

(by Ronen Kolton Yehuda | Messiah King RKY)

Overview

Humans wear a wearable suit or modules (gloves, shoes, sensors, etc.) combined with VR/AR glasses, allowing them to control a remote robot by mirroring their body movements or giving manual commands through a digital avatar interface.

The human can:

Manually operate — move arms, legs, fingers, tools — and the robot mirrors it instantly.

Semi-automatically control — select actions via an avatar panel in AR/VR, and the robot executes.

The Avatar is a virtual, fully-animated version of the user’s body, seen through VR/AR, which acts as an interface between human and robot.

Key Components

Wearable Modules: Sensors on body parts (hands, feet, torso) track detailed motion and pressure.

VR/AR Glasses: Project the robot’s environment into 3D space, and display the digital avatar overlay.

Digital Avatar Interface:

1:1 mirroring of the user’s body.

Command panel for robot actions.

AI-assisted prediction of movements.

Remote Robot:

Physically reproduces the user’s movements.

Can also act semi-autonomously if directed by the avatar panel.

Operation Modes

Example Applications

Remote industrial work (factories, hazardous zones).

Space operations (controlling astronauts' assistants).

Surgical robotics (micro-control over robotic arms).

Rescue operations (operate robots in dangerous disaster areas).

Advantages

High precision and real-time feedback.

Reduces danger to human operators.

Provides multi-task control (manual + semi-automatic).

Enhances human capabilities (lifting heavier loads, super-precision movements).

Hybrid Robots: Combining Manual and Autonomous Control

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

The future of robotics is not purely autonomous or strictly manual — it is hybrid.

Hybrid robots blend the precision and instinct of human control with the speed, endurance, and intelligence of autonomous systems.

This dynamic approach is already transforming industries such as manufacturing, healthcare, defense, and space exploration.

What Is a Hybrid Robot?

A hybrid robot is a robotic system that operates through both manual control and autonomous behavior, switching between modes depending on the task, environment, or human preference.

Operators can:

Directly control the robot’s movement and actions in real-time (manual).

Assign commands or goals that the robot achieves independently (autonomous).

Combine the two approaches, overseeing autonomous actions while intervening when needed.

The transition between manual and autonomous control can be seamless, enhancing flexibility, safety, and operational efficiency.

Key Components

Manual Control Systems:

Wearables (gloves, shoes, exosuits) with sensors to mirror human movements.

VR/AR glasses or digital avatars to provide intuitive control and situational awareness.

Real-time feedback systems (haptics, audio, visual) to inform the operator of robot actions.

Autonomous Systems:

AI-powered decision making based on environmental sensors, cameras, and Lidar.

Task optimization algorithms (path planning, object manipulation, etc.).

Safety protocols for obstacle avoidance, emergency stops, and dynamic environment adaptation.

Hybrid Interface:

An operational dashboard where users can manually pilot, set tasks, or shift autonomy levels.

Digital twin or avatar systems that visualize the robot’s status, options, and environment in VR/AR.

How It Works

Manual Operation:

The operator wears a control system (gloves, glasses) and controls the robot through full-body or hand gestures. The robot mirrors the human’s actions precisely.

Autonomous Execution:

The robot navigates, manipulates, and accomplishes set goals without needing human intervention, using its onboard intelligence.

Seamless Switching:

The operator can intervene at any moment, take over a specific motion manually, or update mission goals in real-time. The system prioritizes fluid transitions between modes to maintain efficiency.

Advantages of Hybrid Robots

Precision + Intelligence: Manual input adds human intuition, while autonomy handles speed and repetitive accuracy.

Adaptability: Robots can work in environments that are unpredictable or complex without overloading the human operator.

Safety: Humans stay at a distance while controlling critical moments directly if needed.

Scalability: One human can oversee multiple semi-autonomous robots simultaneously, reducing manpower costs.

Applications

Industrial Manufacturing: Operate heavy machinery remotely while allowing robots to handle standard processes autonomously.

Search and Rescue: Enter hazardous areas under manual piloting, switch to autonomous search patterns once inside.

Military and Defense: Operate drones or robotic units with manual engagement when precision is needed, autonomous patrol otherwise.

Healthcare and Surgery: Surgeons control robotic arms for critical steps, while autonomous systems handle preparation and stabilization.

Space Exploration: Astronauts manually guide robots for delicate tasks, while autonomous systems conduct routine exploration.

Future Developments

Hybrid robotics will evolve toward greater AI-enhanced intuition, wearable control systems, and digital avatar interfaces.

Future robots will be able to predict when they should shift from autonomous to manual mode based on environment, task complexity, or operator stress levels.

Emerging technologies such as 5G/6G networks, edge computing, haptic feedback suits, and brain-computer interfaces will make hybrid robot operation even more natural and efficient.

Hybrid Robots: The Fusion of Manual Expertise and Autonomous Intelligence

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

The evolution of robotics is entering a new era — one where manual control and autonomous intelligence no longer compete, but merge into hybrid robots.

By combining the instinctive skills of humans with the efficiency and endurance of AI-driven systems, hybrid robots represent a leap forward in how we interact with machines, unlocking a new frontier of precision, safety, and possibility.

What Are Hybrid Robots?

Hybrid robots operate through a dual control system:

Manual Control: A human operator directly pilots the robot using wearable sensors, VR/AR interfaces, and intuitive digital avatars.

Autonomous Control: The robot uses artificial intelligence to make independent decisions, navigate environments, and perform routine or complex tasks without human intervention.

This flexible fusion enables seamless switching between human guidance and robotic autonomy, depending on the needs of the mission.

How Hybrid Control Works

Operator Input:

Using VR/AR glasses and wearable motion trackers, the operator controls a holographic digital avatar.

Movements and commands are transmitted to the remote robot in real-time.

Robot Response:

The robot mirrors manual movements with high fidelity for delicate, high-precision tasks.

Alternatively, the robot can execute autonomous functions such as object manipulation, path navigation, or environment scanning.

Dynamic Mode Switching:

The system constantly analyzes conditions.

If autonomy is more efficient, the robot takes over.

If human judgment is required, manual mode reactivates instantly.

Key Technologies

Wearable Sensor Suits: Gloves, shoes, and body sensors map the human operator’s movements.

VR/AR Interfaces: Visualize both the robot’s environment and the human’s digital avatar for intuitive control.

AI Decision Engines: Allow autonomous goal planning, obstacle avoidance, and error recovery.

Cloud and Edge Processing: Deliver real-time communication and responsiveness even across long distances.

Advantages of Hybrid Robots

Precision and Adaptability: Human intuition handles unique, complex tasks; AI manages repetitive or hazardous activities.

Increased Safety: Operators can control robots in dangerous environments remotely, minimizing human exposure.

Efficiency and Scalability: One operator can supervise or control multiple semi-autonomous units simultaneously.

Skill Enhancement: Augmented reality tools provide real-time suggestions or corrections to operators, improving task performance.

Real-World Applications

Manufacturing and Logistics: Human pilots can guide robots in complex assembly tasks, while autonomy handles standardized operations.

Disaster Response: Hybrid robots can enter dangerous zones autonomously, with humans taking over during rescues.

Healthcare: Surgeons control robotic arms manually for critical steps, while autonomous systems prepare instruments and assist.

Military and Security: Operatives guide drones or ground robots with manual precision for surveillance, then let autonomy take over for routine patrols.

Space Exploration: Astronauts command robotic assistants manually for delicate repairs, while robots autonomously explore distant surfaces.

The Future of Hybrid Robotics

Hybrid robots will become more human-aware, emotionally intelligent, and proactive.

Systems will not just wait for commands but predict operator needs and environmental changes, offering adaptive collaboration.

With advances in 5G/6G, brain-computer interfaces, and quantum AI, hybrid robot ecosystems will redefine industries and daily life.

https://www.kikar.co.il/technology-news/military-humanoid-robots-foundation