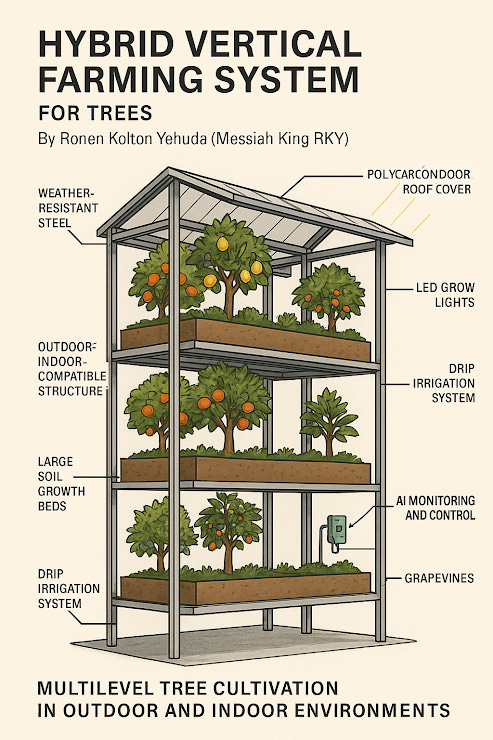

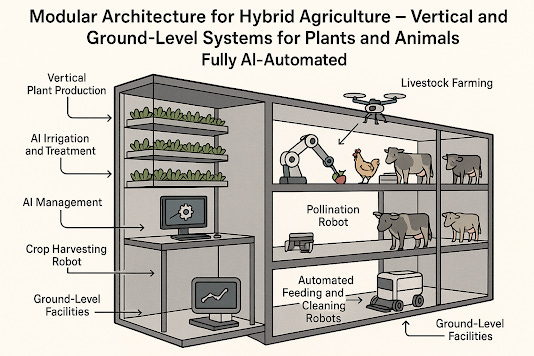

Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

As the global food system evolves, one principle leads the way: flexibility. The future of agriculture is not locked to one method, one terrain, or one form — it is hybrid, modular, and fully AI-automated, capable of adapting to urban towers, rural fields, disaster zones, or planetary colonies. Whether growing plants or raising animals, the infrastructure must support both vertical and ground-level deployment — intelligently managed by autonomous systems that operate without human labor.

This is the vision of hybrid modular agriculture: a universally adaptable architecture for fully automated farming — for plants and animals — designed to maximize yield, efficiency, and ethics in any environment.

🧱 Structural Foundation: One Modular Language

At the heart of this system is a unified modular design, a building-block approach to agriculture where each unit — plant bed, animal habitat, nutrient tank, or processing node — can be:

Stacked vertically or spread horizontally

Replicated, removed, or replaced independently

Assembled quickly in urban, rural, mobile, or underground settings

Plugged into AI-controlled lighting, feeding, watering, treatment, and harvesting systems

These modules can form:

Smart vertical towers with 10–50 floors

Ground-level smart barns and greenhouses

Rooftop farms or basement bio-chambers

Shipping container farms or emergency food bases

Integrated multi-species agro-industrial parks

🌿 Plant Agriculture Modules – Grow Up or Across

Each crop-growing unit is fully AI-managed and includes:

Hydroponic, aeroponic, or soil-based beds

Sensor arrays for root health, moisture, pH, nutrient uptake, and growth stage

LED light panels controlled by the AI for spectrum, duration, and intensity

Irrigation and fertigation lines delivering nutrients drop-by-drop based on real-time data

Climate regulation systems: CO₂, airflow, temperature, humidity, UV filtration

In Vertical Deployment:

Crop beds are stacked on multiple floors, each treated as a microclimate

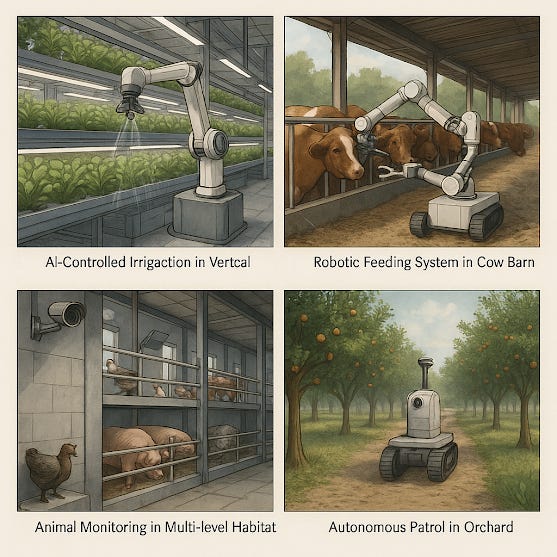

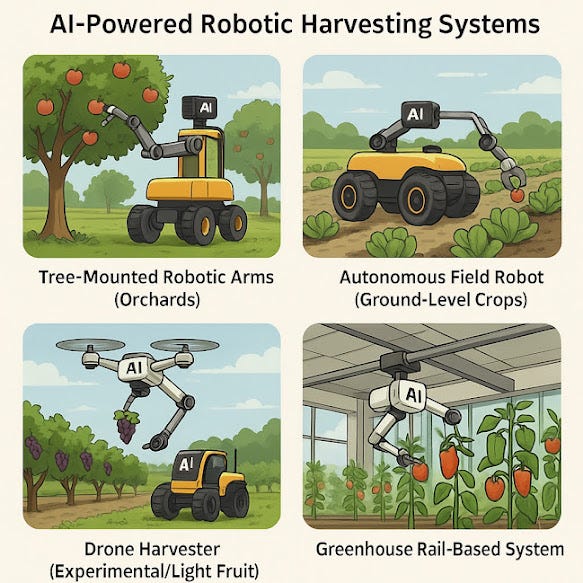

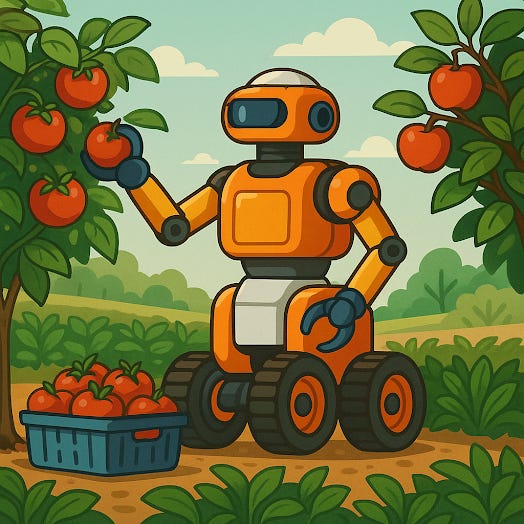

Robotic arms maintain, harvest, and replant automatically

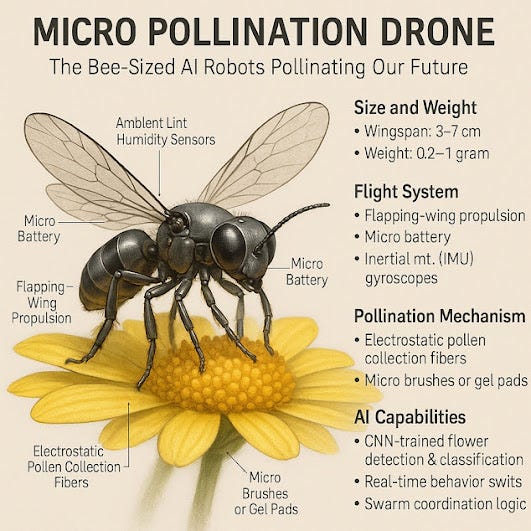

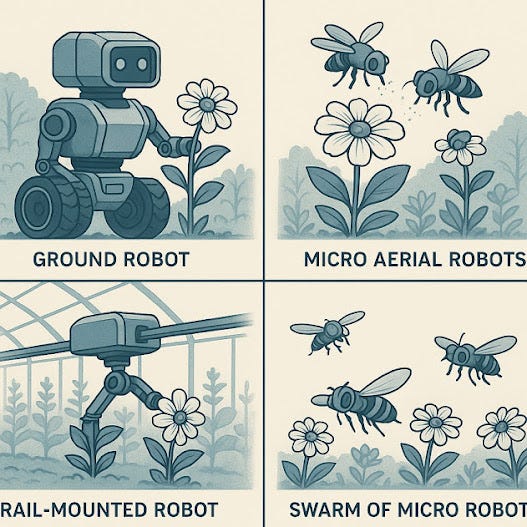

Pollinator drones operate between levels

Solar or grid power supports closed-loop lighting and water systems

In Ground-Level Deployment:

Beds extend horizontally in large halls or greenhouses

AI manages zones row-by-row

Smart tractors or rail-based bots operate across corridors

Outdoor hybrid zones use AI to adapt to real weather conditions

🐄 Animal Agriculture Modules – Intelligent Welfare in Any Shape

Fully AI-automated animal farming depends on detailed environmental control, welfare monitoring, and autonomous care systems. Each animal module includes:

Habitat pods sized per species (poultry, goats, rabbits, dairy cows, aquaculture)

Feeding stations with weight-sensitive, programmable dispensers

Watering systems with flow, purity, and consumption tracking

Smart floors for waste capture, robotic sweeping, and cleanliness tracking

Sensors for health, motion, noise, temperature, and stress levels

CCTV + thermal cameras for behavior and emergency detection

Sound and light modulation for behavioral enrichment and routine regulation

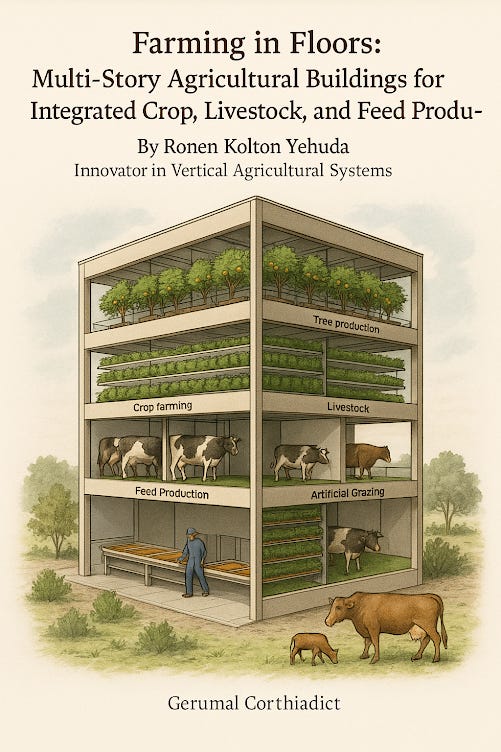

Vertical Livestock Towers:

Floors are dedicated by lifecycle: birthing, growth, production (milk/eggs), rest

Elevators or robotic lifts move supplies or animals (when needed)

Each floor is isolated to prevent contamination

Ideal for cities, where space is limited and biosecurity is critical

Ground-Level Animal Parks:

Long, low-density barns with AI-zoned corridors

Sectioned smart-paddocks or free-roaming enclosed gardens

Robotic cleaners and AI herding drones manage movement and cleanliness

Suitable for scalable, high-volume rural or peri-urban operations

♻️ Shared Systems Between Plants and Animals

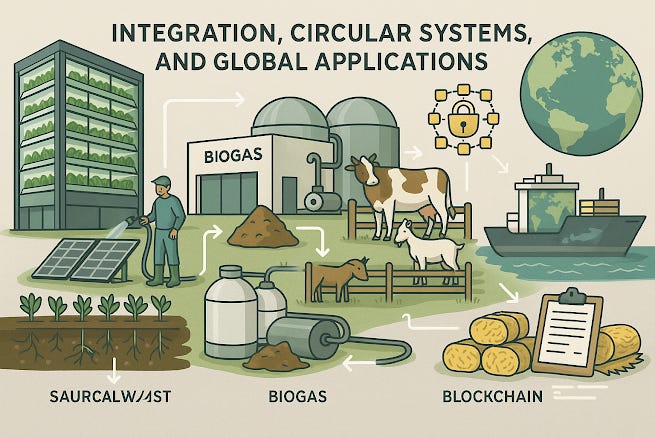

In hybrid farms, plant and animal modules connect to create closed-loop ecosystems:

Animal waste is collected, treated, and converted into fertilizer or biogas

Crop waste becomes animal feed or compost

Water purification systems recycle from both systems

Waste heat from animals warms greenhouses

Insect farming modules convert waste into protein for animals or human consumption

Everything is tracked, optimized, and balanced by the central AI core.

🧠 AI-Centered Infrastructure Logic

What makes this system “fully AI-automated” is the coordination and autonomy of every component:

AI orchestrates irrigation, climate control, feeding, cleaning, harvesting, and animal health

Machine learning models adjust over time based on outcomes and environmental feedback

Predictive analytics prevent diseases, adjust planting schedules, and optimize yield

AI dashboards give human overseers full transparency — but no daily control is needed

The system can run 24/7 without supervision

If an anomaly is detected — whether a nutrient imbalance or an injured animal — the AI responds immediately: applying treatment, isolating units, or dispatching maintenance bots.

🛠 Maintenance and Expansion

The modular architecture allows:

Zero-downtime upgrades: swap a single unit without pausing the system

Scalability on demand: add floors, rows, or zones instantly

Cross-location deployment: replicate units between cities, countries, or disaster areas

Smart servicing: robots inspect and maintain equipment, flagged by predictive diagnostics

🌍 Where It Works

The system adapts to:

Skyscraper farms in dense cities

Smart barns and greenhouses on rural land

Rooftops, warehouses, or underground shelters

Floating structures, arid zones, or refugee settlements

Mobile units deployed in shipping containers

Each location chooses its layout — vertical, ground, or mixed — while the intelligence remains consistent across all.

🔄 Conclusion: Structure That Thinks

This hybrid architecture is not just a frame. It is a thinking infrastructure — built to host life, manage resources, and grow food without supervision. With AI as the central brain and modularity as the backbone, agriculture becomes intelligent by design — adaptable, autonomous, and regenerative.

Whether planted or raised, indoors or out, stacked or spread — food production is no longer constrained. It is fully automated, structurally free, and globally scalable.

Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

The future of agriculture is not linear. It is modular, autonomous, and hybrid — operating both vertically and horizontally, with full integration between plant and animal systems. In a time of climate instability, labor decline, urbanization, and global food insecurity, conventional farming models no longer suffice.

This article presents a comprehensive framework for a Fully AI-Automated Hybrid Agricultural Architecture. Designed to operate in any environment — urban, rural, or remote — the system houses both plant cultivation and animal husbandry across modular, stackable, or ground-deployed units. Every function is managed by intelligent systems: irrigation, feeding, climate control, health, harvesting, and reproduction.

This unified model enables ethical, efficient, and scalable food production — one that is deployable globally, regenerative by design, and prepared for the challenges of the 21st century.

The document is structured in five parts:

Part 1: Foundational Concepts of the Hybrid System

Part 2: Physical Infrastructure and Deployment Formats

Part 3: Daily Operation: AI-Controlled Care and Robotics

Part 4: Health, Ethics, and Reproduction Management

Part 5: Integration with Circular Systems and Global Applications

Part 1: Foundational Concepts of the Hybrid System

This system reimagines agriculture as an intelligent, modular infrastructure, capable of operating:

Vertically in multistory towers

Horizontally on rural lands

In greenhouses, rooftops, underground bunkers, or mobile containers

Whether cultivating vegetables or raising poultry, the architecture follows a unified logic: plug-and-play modules, fully autonomous and centrally coordinated by AI.

Core principles include:

Hybrid layout compatibility: deploy vertical or ground-level

Total AI-automation: 24/7 intelligent operation

Closed-loop integration: between plant, animal, water, and energy systems

Scalability and redundancy: units function independently or together

Ethical design: welfare monitoring, no confinement, environmental enrichment

Global flexibility: deployable in cities, deserts, floating farms, or disaster zones

Part 2: Physical Infrastructure and Deployment Formats

2.1 Modular Building Blocks

Each unit — plant bed, habitat pod, storage cell, or processing node — is:

Stackable vertically or deployable in rows

Interchangeable, transportable, and easily serviced

Connected via universal mechanical and digital ports

Climate-isolated for floor-by-floor or row-by-row zoning

2.2 Crop Architecture

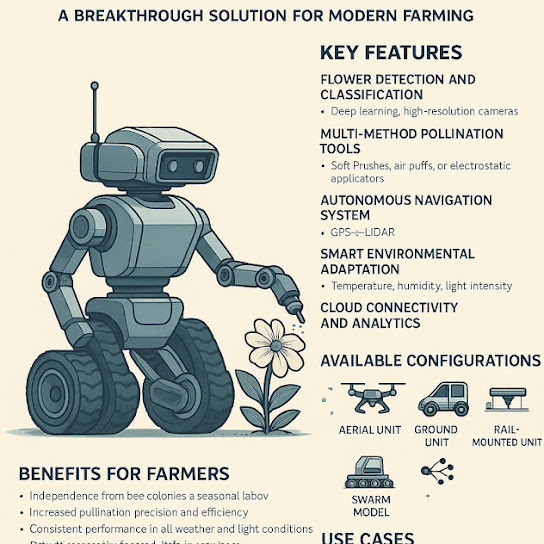

Hydroponic, aeroponic, or soil trays with real-time root sensors

AI-managed LEDs, ventilation, and nutrient delivery

Robotic arms for planting, maintenance, and harvesting

Pollinator drones and smart irrigation nozzles

Vertical farms operate as climate-controlled towers. Ground-level farms use AI-managed greenhouses or horizontal beds.

2.3 Animal Infrastructure

Habitat pods based on species needs (e.g., goats, poultry, fish, rabbits)

Robotic feeders and auto-watering stations

Thermal and biometric sensors

Smart cleaning floors and sound/light modulation systems

Animal zones are arranged vertically (stacked floors) or horizontally (barns, paddocks), each AI-isolated for hygiene and control.

Part 3: Daily Operation – AI-Controlled Care and Robotics

3.1 Feeding and Hydration

AI adjusts feeding formulas per species, age, weight, and condition

Feed and water delivery is scheduled, weight-sensitive, and tracked per animal

Autonomous arms refill dispensers, clean containers, and calibrate dosing

3.2 Cleaning and Waste Management

Floor robots sweep, scrape, and vacuum waste into anaerobic digesters

Water misters disinfect surfaces

Air circulation is filtered, climate-tuned, and ammonia-monitored

All hygiene cycles are auto-triggered by contamination or time thresholds

3.3 Light, Air, and Behavioral Control

LEDs simulate natural day-night cycles

CO₂ and humidity sensors regulate air flow

Cameras detect restlessness, stress, or aggression

AI gates and light cues adjust zones and isolate animals when needed

Part 4: Health, Ethics, and Reproduction Management

4.1 Biometric Monitoring

Vitals tracked: skin temperature, motion, vocalization, posture, breath

Deviations trigger isolation and treatment

Full traceability is logged: from intake to output

4.2 Stress and Behavior

AI detects signs of stress and aggression

Sound and light modulation reduce tension

Enriched zones provide play and rest environments for animals

4.3 Reproductive Systems

Ovulation, fertility, and compatibility tracked

Mating, insemination, and birthing managed by AI with remote vet alerts

Animals rotate ethically, with lifecycle scoring and audit logs

Part 5: Integration with Circular Systems and Global Applications

5.1 Closed-Loop Systems

Waste-to-fertilizer or biogas conversion

Crop waste as feed or compost

Heat sharing between animal and plant zones

Water reuse between hydration and irrigation channels

5.2 Energy and Climate Adaptation

Compatible with solar, biogas, or grid power

Battery storage and smart scheduling

Designed for heatwaves, floods, and cold regions

5.3 Global Deployment Models

Urban towers with food independence

Rural smart barns with AI control

Emergency container farms for disaster zones

Floating farms or underground bunkers

Traceable, certifiable, ethical global export

Conclusion: Thinking Infrastructure for a Sustainable Food Future

This fully AI-automated, modular, hybrid agricultural system redefines what it means to farm. It is not a factory, but a self-operating ecological network — as responsive as it is resilient. Whether deployed in megacities or refugee camps, this system provides:

Consistent yield with reduced land, water, and labor

Ethical treatment through data-driven welfare control

Circular integration with energy, climate, and waste systems

Global compatibility across all ecosystems and economies

It is infrastructure that thinks, heals, feeds, and adapts — built to endure and regenerate, not exploit and exhaust.

This is not the automation of the old. It is the architecture of the next.

Part 1: Foundational Concepts of the Hybrid System

From the Series: Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

1. Introduction

The global food system is entering a phase of structural transformation. Pressures such as population growth, land scarcity, climate volatility, rising ethical standards, and resource constraints demand a comprehensive redesign of how we produce both plant-based and animal-based food.

Conventional agriculture — whether in open fields or concentrated industrial barns — is inherently limited in adaptability, traceability, and efficiency. These legacy systems are spatially rigid, labor-dependent, and highly resource-intensive.

This first part outlines the foundational principles behind a new model: a modular, hybrid, and fully AI-automated agricultural infrastructure capable of growing crops and raising livestock in both vertical and horizontal formats, across any climate, geography, or emergency setting.

2. Hybrid Deployment Logic

The system is hybrid in two dimensions:

2.1 Structural Hybridization

Vertical deployment: High-density towers or multilevel structures in urban, industrial, or space-limited zones.

Ground-level deployment: Horizontal farms in rural, peri-urban, or remote environments.

Mixed deployments allow both crops and animals to coexist in hybrid agri-complexes — adapted to the needs of cities, islands, deserts, or shelters.

2.2 Cross-Species and Cross-Function Hybridization

Plant and animal systems share a unified modular infrastructure: growing beds, habitat pods, environmental control panels, and AI cores.

Modules are interchangeable, reconfigurable, and jointly orchestrated by a central AI.

Species-specific adjustments are implemented at the module level: light, air, water, feed, humidity, noise, rest, and harvesting.

3. Core Components of the System

3.1 Modular Infrastructure

Each agricultural function (e.g., feeding, growing, climate regulation) is hosted within a discrete, physically interchangeable module.

Modules are:

Plug-and-play: Compatible with unified connectors (data, energy, water, waste)

Scalable: Deploy one or thousands across locations

Redundant: Systems remain operational even if individual modules are replaced or repaired

3.2 Autonomous Operation via AI

Feeding, irrigation, harvesting, cleaning, climate control, animal health monitoring, and pollination are managed through AI algorithms.

No daily human presence is required — AI systems execute tasks, detect anomalies, and request assistance if needed.

AI models are trained on species-specific, crop-specific, and climate-specific parameters, adapting over time via machine learning.

4. Ethical and Functional Goals

4.1 Spatial Efficiency

Enables food production in dense urban areas, marginal lands, rooftops, or underground spaces.

Vertical farms reduce land use by up to 90% compared to field farming.

Ground-level smart barns reduce pasture demand and optimize logistics.

4.2 Climate and Resource Efficiency

Closed-loop energy, water, and nutrient systems minimize waste.

AI-adaptive lighting and airflow save energy.

Water is captured, purified, and reused.

4.3 Welfare and Transparency

Animals are housed in non-confinement enriched environments with biometric monitoring.

Crops grow in pesticide-free, sensor-controlled conditions.

Every process is traceable, auditable, and algorithmically accountable.

5. Applications and Environments

This architecture is designed for deployment in:

Urban agri-towers (dense cities, smart infrastructure projects)

Rural smart farms (large-scale animal and crop integration)

Climate-unstable zones (arid, flood-prone, or cold regions)

Emergency and refugee settings (containerized mobile farms)

Off-grid environments (military bases, island nations, or future space colonization)

Each unit may operate:

Independently (e.g., micro-farm or test site)

As part of a networked farm grid, coordinated by regional or global AI infrastructure

6. Strategic Implications

Food Sovereignty: Localized, vertically scalable production reduces reliance on imports and global supply chains.

Climate Adaptation: Operates resiliently in heat, cold, drought, or isolation.

Labor Transition: Relieves dependency on scarce agricultural labor.

Food Safety and Certification: Outputs meet high standards for hygiene, nutrition, and ethics — traceable from seed or birth to plate.

7. Conclusion

This hybrid, modular, AI-operated architecture is not an alternative to agriculture — it is its logical next stage. By allowing vertical and horizontal deployments for both crops and animals under fully autonomous control, it resolves fundamental bottlenecks in land use, ethics, productivity, and environmental impact.

In the sections to follow, we will detail how this infrastructure is physically designed, how its daily operations are executed, how welfare and health are monitored, and how it integrates into global food systems.

Part 2: Physical Infrastructure and Deployment Formats

From the Series: Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

1. Introduction

The successful realization of a fully AI-automated hybrid agriculture system depends on a flexible, scalable, and environmentally adaptive physical infrastructure. The architecture must serve two simultaneous goals: maximize spatial efficiency through vertical stacking and ensure accessibility, scalability, and stability through ground-level deployment.

This part describes the technical foundation of the system’s modular structure — detailing how plant and animal environments are physically organized, controlled, and integrated. Whether in a city tower or rural field, the physical components remain consistent in logic and function.

2. Core Principles of Modular Design

2.1 Structural Modularity

Every unit — from plant bed to animal habitat to climate module — is designed as a standalone functional module.

Modules feature:

Standardized interfaces (power, water, data, waste lines)

Plug-in connectors for seamless expansion or substitution

Quick-deploy frameworks (no foundation needed for container systems)

2.2 Hybrid Configurability

Vertical Deployment: Stackable modules in multistory towers (10–50 floors), optimized for high-yield urban production or isolated compact sites.

Ground-Level Deployment: Horizontally arranged modular barns, greenhouses, aquaponic paddocks, or shipping container clusters.

3. Infrastructure for Plant Systems

3.1 Vertical Plant Deployment

Hydroponic and aeroponic beds are stacked in vertical racking systems.

Each floor or rack includes:

Sensor arrays (pH, nutrient levels, temperature, CO₂, light intensity)

AI-directed LEDs for precision spectrum and cycle control

Automated nutrient and water delivery

Robotic harvest arms

Air and water move through a looped circulation grid, monitored continuously.

3.2 Ground-Level Plant Layouts

Horizontal greenhouse arrays, optionally open to weather-adaptive AI panels.

Soil-based beds for specific crops, with robotic plows or micro-tractors.

AI manages zone-specific variables (light angle, airflow, drip rates).

Corridors support robotic logistics and mobile AI harvesters.

4. Infrastructure for Animal Systems

4.1 Vertical Animal Deployment

Modular animal floors are configured by lifecycle: birth, rearing, production (milk/egg), and rest.

Each floor contains:

Species-specific enclosures (e.g., goats, chickens, rabbits, aquaculture tanks)

Feeding and watering dispensers

Climate, waste, sound, and lighting control

CCTV and thermal behavior sensors

Automated cleaning systems (misters, floor scrapers, UV gates)

Elevators or lifts manage supply transport and animal access when necessary.

4.2 Ground-Level Animal Layouts

Large barns or low-density smart paddocks arranged in corridor-linked modules

AI-controlled ventilation, hydration, and feeding infrastructure

Movable fences or virtual zoning using sensory collars

Waste capture zones connected to biodigesters

Ideal for high-volume rural applications and regional cooperative farming

5. Shared and Cross-System Integration

5.1 Infrastructure Sharing

Waste recycling systems: Animal byproducts fertilize crop beds or fuel biogas generators

Shared climate systems: Waste heat from animals warms nearby crops

Water reuse: Purified water loops between systems, minimizing draw

Nutrient and light feedback: AI balances plant and animal rhythms for energy efficiency

5.2 Operational Consistency

Regardless of layout:

Sensor logic is standardized (data formats, thresholds, calibration)

AI protocols are interoperable across plant and animal units

Servicing is modular: Any module can be repaired, replaced, or upgraded without systemic downtime

6. Maintenance, Expansion, and Transportability

All modules are designed with:

Self-cleaning surfaces

Predictive maintenance AI agents

Redundant data storage and local controllers

Modules can be:

Re-deployed to new sites

Shipped in ISO containers

Expanded vertically or horizontally without redesign

7. Applications by Setting

Setting Deployment Format Output Focus

Urban rooftops Vertical/lightweight Leafy greens, poultry, fish

Rural smart farms Horizontal modular barns Dairy, meat animals, soil crops

Conflict/disaster zones Containerized hybrid units Emergency food resilience

Arctic/desert locations Insulated vertical stack Indoor vegetables, aquaculture

Offshore/floating zones Waterproof container modules Fish, algae, waste treatment

8. Conclusion

The strength of this agricultural model lies in its architectural neutrality and modular consistency. Whether stacked in dense cities or distributed across open land, the system functions identically at the operational level.

It supports rapid deployment, continuous scalability, and physical redundancy. Most critically, it makes no structural distinction between plants and animals — they are managed within the same logic framework, by the same intelligent core, with the same sustainability principles.

Next, we explore how this infrastructure operates on a daily basis: how machines, sensors, and algorithms deliver fully autonomous care — without dependency on human labor.

Part 3: Daily Operation – AI-Controlled Care and Robotics

From the Series: Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

1. Introduction

The heart of any fully automated agricultural system lies not only in its structure, but in its capacity to perform and sustain complex daily operations without human intervention. Feeding, hydration, climate regulation, health monitoring, harvesting, cleaning, and behavioral modulation — all must occur in synchrony, governed by data and executed by machines.

This section details the daily operations of the hybrid system, orchestrated by AI and robotics, across both plant and animal modules. These systems work continuously, intelligently, and predictively — ensuring efficiency, sustainability, and biological well-being.

2. System Architecture and Control

2.1 Distributed AI Governance

Each module is embedded with:

Local microcontrollers and edge-computing units

Sensor arrays for specific functions (e.g., light, pH, weight, movement, humidity)

Communication relays to a central AI or cloud AI for macro-coordination

The AI governs all daily tasks based on:

Real-time sensor feedback

Behavioral modeling

Historical performance data

Environmental conditions

Operational priorities and yield optimization algorithms

3. Feeding and Hydration Systems

3.1 Animal Feeding

Robotic dispensers release precise rations based on species, age, weight, and health.

Multiple feed types (e.g., grain, hay, pellets, protein supplements) can be blended in real time.

AI tracks intake patterns to detect anomalies such as illness, stress, or crowding.

3.2 Plant Nutrition (Irrigation + Fertigation)

Nutrients are delivered in dissolved form via mist, drip, or circulation systems.

AI regulates:

Frequency

Dosage

Mineral composition

pH and EC levels

Excess water is captured, purified, and re-circulated.

3.3 Hydration Monitoring

Flow meters and quality sensors track consumption and purity.

Dosing can include vitamins, electrolytes, or probiotics as prescribed by AI models.

Alarms are triggered if hydration falls below safe thresholds.

4. Environmental Control Systems

4.1 Climate Regulation

Each module is a climate-isolated cell with controlled:

Temperature

Airflow

Humidity

CO₂ or ammonia concentration

Ventilation is adjusted continuously via actuators, fans, and filters.

4.2 Lighting and Circadian Management

Full-spectrum LEDs mimic day-night cycles based on:

Crop or species

Latitude

Behavior data

Light intensity, duration, and spectrum shift in real time to optimize growth or rest.

4.3 Sound and Behavioral Acoustics

AI listens for vocal distress, restlessness, or excessive silence.

Soothing or enriching soundscapes can be applied.

Noise levels are dynamically regulated to prevent chronic stress.

5. Movement, Activity, and Social Monitoring

Cameras and floor sensors map movement and interaction patterns.

In animals: pacing, lying, pecking, herding, or isolation patterns are analyzed.

In plants: growth curvature, leaf coloration, and posture are assessed via vision systems.

AI adjusts environments to:

Separate aggressive animals

Encourage natural rest/play cycles

Support optimal exposure to light or airflow for plants

6. Cleaning and Sanitation Automation

6.1 Animals

Floors cleaned via robotic scrapers, vacuums, and misters

Enclosures sanitized with non-toxic vapors or UV light

Bedding, manure, and spilled feed are collected and processed

Waste streams routed to anaerobic digesters or compost tanks

6.2 Crops

Plant zones flushed with clean water or mist

Pathogen detection via spectral analysis triggers microdisinfection

Trays or scaffolds are cleaned robotically during off-light cycles

7. Harvesting and Handling

7.1 Crops

Robotic arms with pressure-sensitive grippers harvest mature produce

AI selects harvest timing based on:

Growth curves

Nutrient analysis

Consumer preference (e.g., ripeness or starch level)

Sorting and packaging are executed on-site by conveyors and labeling bots

7.2 Animal Product Collection

Egg collection belts

Automated milking machines with real-time flow and quality sensors

Weight tracking for meat or wool production readiness

AI flags for rotation, fertility, or retirement based on performance history

8. Alerts and Oversight

Human managers receive alerts only in case of:

System malfunction

Emergency illness

Infrastructure breach

AI dashboards visualize:

Operational efficiency

Animal welfare score

Plant growth rate

Environmental resource usage

Manual intervention is rare, but always enabled.

9. Summary

In this architecture, daily agricultural activity is no longer a series of human-led routines. It is a perpetual, learning, self-balancing machine ecosystem, guided by algorithms that observe, evaluate, and act — all while preserving energy, water, and biological health.

Wherever food is produced using this system — in towers or fields, cities or deserts — the rules of operation remain identical. Only the geometry changes. Intelligence stays constant.

Part 4: Health, Ethics, and Reproduction Management

From the Series: Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

1. Introduction

One of the most transformative aspects of AI-automated agriculture lies in its capacity to deliver continuous, data-driven care for living organisms — optimizing health outcomes, reducing suffering, and eliminating arbitrary handling. In this system, both animal and plant welfare are monitored, interpreted, and protected by algorithms trained on biological patterns, not economic shortcuts.

This section presents the architecture's ability to autonomously manage biometric health tracking, disease prediction, stress monitoring, and ethical lifecycle management — particularly for livestock — including reproduction, aging, and rotation. The system also provides complete traceability for audit, certification, or scientific oversight.

2. Biometric Identification and Continuous Monitoring

2.1 Animal Identification

Each animal is tagged using:

RFID implants, smart collars, or subcutaneous NFC

Facial recognition for larger mammals

Gait and behavior-based re-identification for small livestock (e.g., rabbits, poultry)

Each ID is linked to a real-time biometric profile, updated continuously

2.2 Vital Signs Monitoring

Sensor types include:

Infrared thermography (core temperature detection)

Sound mapping (respiration, vocal stress)

Posture sensors (limping, lying down too long, injury)

Feed and water consumption logs

Camera-based gait and microexpression recognition

The system builds individualized baselines for each animal, allowing the AI to detect anomalies before visible symptoms arise.

3. Predictive Health and Veterinary Logic

3.1 Early Illness Detection

When deviations exceed thresholds:

The animal is automatically segregated via robotic gates

Ambient conditions are adjusted (heat, airflow, noise)

AI generates a probability diagnosis

Human overseers receive a full behavior and vitals log

This proactive approach reduces mortality, prevents spread, and eliminates guesswork.

3.2 Disease Prevention and Immunization

The system:

Tracks immunization schedules

Adjusts microdosing based on immune response

Manages isolation chambers and reintroduction logic

Performs environmental decontamination as required

4. Stress and Behavioral Health Systems

Animals often exhibit signs of stress that precede visible health effects. The system uses behavior-based AI to manage comfort and enrichment.

4.1 Stress Signals

Detected via:

Vocal anomalies

Increased restlessness or stillness

Social aggression

Abnormal feeding or drinking rates

4.2 Responsive Adjustments

AI reacts by:

Adjusting lighting and soundscapes

Activating calming pheromone diffusers (if species-appropriate)

Separating individuals into rest pods

Increasing monitoring frequency

5. Reproductive and Lifecycle Control

5.1 Reproduction

Fertility is managed via:

Motion and hormone-response indicators

Ovulation and cycle predictions

Controlled mating or insemination timing

Birth environment preparation (heat, privacy, bedding)

AI automates:

Pairing schedules

Breed optimization (if permitted)

Postnatal care parameters

Litter tracking and growth milestones

5.2 Lifecycle and Rotation

Animals are rotated through stages (e.g., milk/egg production, resting, reproduction) based on biological signals, not fixed quotas

Retirement is flagged by the AI using:

Productivity decline

Reproductive fatigue

Health deterioration

The system maintains life history records and ethical flags for each animal, including euthanasia protocols (only if permitted by regulation)

6. Welfare Scoring and Transparency

Each module generates an ongoing welfare index composed of:

Health stability

Stress detection

Activity balance

Cleanliness metrics

Mortality avoidance

Growth and recovery rates

These scores are:

Logged in tamper-resistant databases

Auditable by third parties

Visualized for institutional dashboards

Optionally broadcast to transparency portals or certification agencies

7. Parallel Systems for Plant Health

Plants are monitored for:

Growth trajectory

Nutrient uptake efficiency

Leaf coloration and orientation

Disease or fungal spotting

Stress due to light, root density, or CO₂

Responses include:

Adjusting nutrient flow

Pruning via robotic arms

Redirecting light or airflow

Swapping beds or isolating rows for sterilization

8. Conclusion

The daily ethics of agriculture must move beyond reaction and regulation. With AI-powered biometric systems, ethical care becomes proactive, quantifiable, and standardizable.

Animals are no longer seen as anonymous assets — they are data-rich individuals whose wellbeing is embedded into the function of the architecture itself. Plants are treated as complex, living systems, not passive inputs.

This is not only a model of precision — it is a model of principled intelligence, scalable and exportable across all regions of the world.

Part 5: Integration, Circular Systems, and Global Applications

From the Series: Modular Architecture for Hybrid Agriculture – Vertical and Ground-Level Systems for Plants and Animals (Fully AI-Automated)

By Ronen Kolton Yehuda (Messiah King RKY)

1. Introduction

No agricultural system can claim to be sustainable without integrating resource efficiency, ethical logic, environmental circularity, and global adaptability. The final layer of the hybrid modular system is its integration with surrounding systems — water, energy, waste, logistics, and institutional networks — creating a model that is not only closed-loop but planet-ready.

This section presents how the architecture links plants and animals to one another and to broader infrastructure — forming a self-sustaining, data-integrated food ecosystem that is deployable in both developed and resource-constrained contexts.

2. Circular Resource Loops

2.1 Water Management

Water is cycled between:

Animal hydration and waste → filtration → irrigation

Plant evapotranspiration → condensation recovery → reuse

Surface cleaning systems → greywater separation → recirculation

AI ensures:

Clean vs. dirty stream distinction

Continuous micro-purification

Emergency storage control

Aquifer recharge and rain harvesting where applicable

2.2 Energy Recovery and Biogas

Manure, spoiled crops, and waste feed are funneled into anaerobic digesters

Methane is harvested for electricity and heating

Waste heat from livestock is redirected to nearby plant modules

Optional solar, wind, and battery layers provide resilience

3. Waste and Fertilizer Logic

Plant residues feed herbivorous animals

Animal waste is:

Separated (liquid vs. solid)

Converted into fertilizer

Measured and injected into plant systems through AI-dosed fertigation

Insect farming (e.g., black soldier flies) can convert both waste streams into protein or compost

Every output becomes another input — creating zero-waste loops with AI optimization.

4. Food System Integration

4.1 Traceable Output Streams

All plant and animal products are:

Digitally tagged (origin, date, growth metrics, care data)

Certifiable by blockchain or institutional audit

Stored with real-time location and welfare history

This enables:

Ethical labeling

Smart export management

Institutional supply chain integration (hospitals, military, education)

4.2 Local vs. Global Deployment

The same architecture can be:

Used in hyperlocal food sovereignty for cities or islands

Exported as containerized farms to remote populations

Scaled up for national food independence projects

Deployed as a backup food network for war, disaster, or space colonies

5. Application Environments

Environment Deployment Type Key Features

Dense urban centers Vertical towers or rooftop units Minimal land use, co-located with utilities

Rural/peri-urban zones Horizontal modular fields High-volume animal and crop output

Refugee or crisis areas Containerized mobile farms Emergency protein and crop generation

Islands or deserts Solar-hybrid, water-recovery farms High efficiency, closed water loop

Arctic zones Insulated vertical stacks Thermal control and nutrient cycling

Floating/offshore units Modular water-farms Aquaculture + desalination + solar energy

6. Institutional and Scientific Integration

AI dashboards can be shared with regulators, scientists, and oversight agencies

Ethical certifications (e.g., organic, cage-free, sustainable) can be granted based on real-time data

Universities and R&D centers can plug into live systems for continuous experimentation

Systems can connect to national food resilience grids and AI-enabled disaster response protocols

7. Global Ethical Impact

By eliminating:

Confinement farming

Open-loop pollution

Manual mistreatment

Genetic overloading and unnatural acceleration

...this model proposes a bioethically coherent food system — where AI serves life, and not the other way around.

Products grown in this system may:

Earn carbon credits

Carry premium ethical labeling

Qualify for climate grants or urban planning incentives

Become legal baselines for future agri-policy

8. Conclusion

The modular, hybrid, fully automated agricultural system is not an innovation in isolation — it is a convergent model that unites biology, computing, ethics, and sustainability under a single infrastructure.

By fusing vertical and horizontal formats, plant and animal systems, closed loops and open networks, this architecture offers a complete, climate-adaptable, and humane solution to the planetary food challenge.

It is not just agriculture for now — it is agriculture for everywhere, and for what comes next.

Fully AI-Automated Plant Agriculture System — Vertical Plant Growth on Multiple Levels

Hybrid Vertical Farming System: A Scalable Framework for Growing Trees, Crops, and…

____________________________________