Secure Indoor Farming Systems: Integrating Livestock and Crops in Fortified Environments for Resilient Food Sovereignty

Farming in Bunkers: Secure Indoor Agriculture for Crops, Animals, and Livestock in Times of Crisis

Secure Indoor Farming Systems: Integrating Livestock and Crops in Fortified Environments for Resilient Food Sovereignty

By Ronen Kolton Yehuda (Messiah King RKY)

Founder of Villan | Visionary of Future-Resilient Infrastructure

Abstract

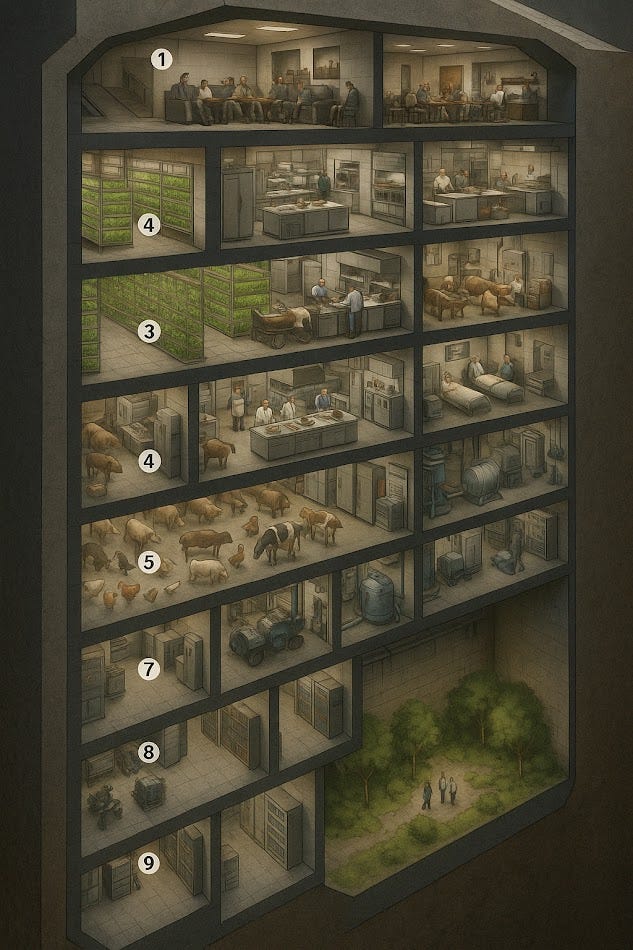

In response to modern warfare, climate emergencies, pandemics, and strategic isolation, the need for autonomous and protected food systems has never been more critical. This paper proposes a holistic model for secure indoor farming, combining animal husbandry, crop cultivation, and artificial grazing systems within fortified environments such as bunkers, bomb shelters, subterranean facilities, and military bases. The proposed system addresses food security, livestock welfare, energy independence, and scalability, forming a blueprint for sovereign sustenance under extreme conditions.

1. Introduction

Traditional agriculture is vulnerable to external disruptions — from missile strikes and contamination to climate collapse. As strategic threats and environmental instability rise, sovereign actors require closed-loop food systems capable of operating underground or within shielded enclosures, immune to surface-level collapse.

This paper presents a multi-species, multi-crop modular farming system, with an emphasis on indoor security-based deployment, for both civilian resilience and military sustainment.

2. System Architecture

2.1. Structural Design

Deployment Zones: Underground bunkers, repurposed tunnels, fortified basements, mobile container farms, military shelters.

Materials: Reinforced concrete, lead lining (radiation), air filtration membranes, temperature insulation.

2.2. Core Subsystems

Hydroponic & Aeroponic Grow Zones

Artificial Grazing Field with UV-safe lighting

Multi-species Livestock Housing

Biowaste & Fertilizer Conversion

Renewable Energy Infrastructure

Water Recycling & Atmospheric Extraction

3. Indoor Crop Cultivation

3.1. Vertical Hydroponics & Aeroponics

Crops: Leafy greens, tomatoes, potatoes, herbs, algae, legumes.

Lighting: Full-spectrum LED arrays simulating solar cycles.

Irrigation: Closed-loop nutrient delivery with AI feedback.

Climate Control: Humidity, CO₂ enrichment, pathogen control.

3.2. Feed Production

Sprouted Grains (Barley, Alfalfa) for livestock feed.

Dehydrated Feed Blocks for long-term emergency use.

4. Secure Indoor Animal Husbandry

4.1. Ruminants (Cattle, Goats, Sheep)

Habitats: Padded flooring, controlled air circulation, artificial daylight cycles.

Artificial Fields: Grazing simulators with turf or synthetic vegetation, designed for hoof health and muscle movement.

Milking Systems: Automated units with health diagnostics and yield tracking.

Manure Conversion: Digesters turning waste into methane and organic fertilizer.

4.2. Poultry (Chickens, Ducks)

Automated Coops: Nesting, laying belts, roosting, air scrubbing.

Egg Harvesting: Conveyor and AI egg-quality scanning.

Feather shedding & Molting environments: Timed lighting cycles.

4.3. Micro-livestock (Rabbits, Pigeons, Fish)

Small habitat modules for protein-rich food sources with minimal noise and space requirements.

Aquaponic Integration: Fish waste to plant fertilizer.

5. Artificial Pasture & Livestock Movement

To address behavioral and physiological needs of large animals:

Artificial Pasture Zones: UV-balanced lighting, textured grass-like flooring.

Walk Loops & Treadmills: Maintain joint and digestive health.

Enrichment: Robotic interaction, music, and sensory stimulus for animal well-being.

6. Power and Water Independence

6.1. Energy

Solar, Wind, and Biogas Hybrid Systems

Battery Storage Units

Failover Diesel/Electric Generators (optional)

6.2. Water

Atmospheric Water Generators (AWGs)

Greywater Treatment

Reverse Osmosis Filtration for drinking and irrigation

7. Applications and Use Cases

Use CaseFunctionMilitary InstallationsLong-term deployment independenceCivilian BunkersEmergency survival and food sovereigntyConflict ZonesNon-disruptible nutrition infrastructureRemote Research StationsSustained life-support ecosystemUnderground CitiesPermanent urban-agro integration

8. Ethical and Security Considerations

Animal Rights in Confined Environments

Zoonotic Risk Management

Bioterrorism Shielding

Food Ethics During Conflict

9. Future Development & AI Integration

AI-powered animal health tracking

Drone-assisted indoor monitoring

Predictive agricultural modeling using Villan VI (Villan Intelligence)

Genetic optimization of crops for low-light, fast-yield environments

10. Conclusion

Indoor farming with integrated animal systems in secure shelters presents a viable, scalable, and sovereign approach to global food resilience. Whether in preparation for war, climate collapse, or space colonization, these modular systems offer continuity of civilization through autonomy in nutrition.

Keywords: indoor farming, secure agriculture, artificial pasture, bunkers, livestock, hydroponics, food sovereignty, disaster resilience, fortified food systems, climate-proof farming

Certainly. Here is an expanded version of the AgroShield system that now includes indoor fruit tree farming — such as citrus, figs, apples, bananas, and dwarf or trellised orchard systems — all integrated within fortified environments like bunkers, shelters, and underground bases.

🏛️ AgroShield+

Secure Indoor Farming Systems Including Livestock, Crops, and Fruit Trees in Fortified Environments

By Ronen Kolton Yehuda (Messiah King RKY)

Founder of Villan | Visionary of Future-Resilient Infrastructure

New Component: Fruit Tree Farming in Indoor Bunkers

🍊 Why Fruit Trees?

In addition to vegetables, grains, fish, and animals, fruit trees are critical for long-term nutrition, offering:

Vitamins & antioxidants (Vitamin C, A, potassium, fiber)

Caloric density in bananas, avocados, and dried fruits

Psychological comfort through color, taste, and natural aroma in confined environments

🍋 1. How to Grow Fruit Trees Indoors in Bunkers

🪴 1.1 Dwarf & Trellised Fruit Tree Systems

Use dwarf or semi-dwarf varieties of citrus, figs, mulberries, apples, plums, and olives

Trees are trained vertically using trellis frames, espalier techniques, or multi-tier pots

Pruned to 1.5–2.5 meters height for space efficiency and maintenance

☀️ 1.2 Artificial Sunlight & Flowering

Full-spectrum LED grow lights simulate natural day/night cycles

Lighting cycles vary: 10–14 hours/day for flowering and fruiting

Pollination support via hand-pollination, air fans, or AI micro-drones

🌡️ 1.3 Climate Zones by Fruit Type

Fruit Type Temperature Range Humidity Notes Citrus (Lemon, Orange) 20–28°C 45–60% Needs high light and warm soil Fig 18–26°C 50–70% Prunes well and fruits quickly indoors Apple (Dwarf) 15–22°C 40–60% Requires chill simulation in off-season Banana (Miniature) 22–30°C 60–80% High water, high light Pomegranate 20–28°C 40–50% Thrives in dry, semi-arid controlled zones

🛠️ 2. Technical Setup for Indoor Fruit Zones

2.1 Grow Room Design

Tree beds: Raised or modular planters with drain control

Ventilation: Humidity control + CO₂ injection for photosynthesis

Climate Curtains to divide microclimates inside the shelter

2.2 Soil and Water

Use custom soil mixes or coco coir with perlite for drainage

Integrated drip irrigation system with AI nutrient dosing

Greywater reuse with final RO-purified water for sensitive trees

2.3 Lighting Arrays

LED Grow Panels (3500–4000K for full spectrum + IR & UV channels)

Adjusted seasonal lighting profiles for simulating flowering and dormancy

🌲 3. Integration with the AgroShield Ecosystem

Fruit trees complement animal manure fertilizer loops

Fallen leaves or pruned branches fed into biomass digesters

Dried fruits and preserved jams become nutrient-dense rations

Pollinators (e.g., indoor bee micro-habitats or robotic drones) support both trees and crops

🌍 4. Strategic Advantages

Feature Impact Multivitamin Yield Reduces malnutrition in prolonged isolation Psychological Support Maintains mental health and morale in closed environments Natural Air Filtration Trees help with CO₂ scrubbing and fresh oxygen production Scalable Integration From 2 trees in small shelters to 100s in military-scale bunkers

✅ Additions to Use Cases

Deployment Site Fruit Trees Role Civilian Shelters Local vitamin & sugar source Military Bases Long-duration rations & morale Arctic Bunkers Natural oxygen & preserved fruit Subterranean Colonies Closed-loop fruit ecosystems Mars/Space Simulators Resilience in space food systems

🧠 AI-Managed Orchard

Tree health sensors monitor growth, leaf status, soil moisture

AI pruning guidance

Pollination bots map flowering cycles and assist automatically

Harvest optimization ensures peak nutrient value and storage readiness

🏁 Conclusion

The inclusion of fruit trees makes AgroShield a complete sovereign food ecosystem, not just an emergency survival system. It supports physical health, mental wellness, biodiversity, and full-circle sustainability, all from within concrete walls.

Whether in a bunker, underground city, or space colony — life must continue with dignity, nutrition, and nature.

Technical Article: Secure Indoor Farming and Enclosed Livestock Systems for Conflict Zones and Bunkers

By Ronen Kolton Yehuda (Messiah King RKY)

Founder | Villan | 1 Holdings & Investments

1. Objective

This article outlines the technical framework for a self-sufficient indoor farming system that integrates crop production and animal husbandry within fortified or subterranean environments, such as bunkers, bomb shelters, and conflict-zone compounds. The goal is to maintain year-round food production under threat conditions — immune to external shocks like war, climate events, or supply chain failure.

2. System Overview

The system is built around the following core modules:

ModuleFunctionVertical Crop FarmVegetables, herbs, fruits using hydroponics/aeroponicsLivestock ChambersDairy and meat production from cows, sheep, goats, pigsPoultry ChambersEgg and meat production from chickens, ducksArtificial Grazing FieldsSimulated open field space for animal welfare and movementFish Farming UnitRecirculating aquaculture system (RAS)Feed Production LabSprouted grains and silage for animalsWater & Waste TreatmentFiltration, recycling, and biogas energyPower UnitRenewable and backup energy systems

3. Crop Farming Unit

3.1 Infrastructure

Structure: Modular vertical frames made of corrosion-resistant aluminum.

Enclosure: Sealed walls with insulation, CO₂ injection ports, and UV-blocking layers.

Lighting: LED grow lights (PAR-optimized, ~400–700nm range).

Growth Medium: Rockwool, coco coir, or aeroponic misting chambers.

3.2 Environmental Control

Temperature: 18–24°C via HVAC with HEPA filters.

Humidity: 40–70% RH via automated misting/dehumidifiers.

Irrigation: Closed-loop hydroponic drip systems with nutrient reservoirs and pH/EC sensors.

Automation: PLC-based system with remote monitoring and AI scheduling.

4. Enclosed Livestock System

4.1 Livestock Housing

Species: Cows, goats, sheep (dairy/meat); pigs (meat).

Flooring: Non-slip rubberized antimicrobial material with drainage.

Ventilation: High-CFM airflow with carbon and ammonia filters.

Light Cycle: Adjustable LED to simulate day/night.

4.2 Animal Health Monitoring

Wearable Sensors: Heart rate, temperature, step count, rumination.

Camera Systems: 360° cameras with AI-based posture/stress recognition.

Milking: Automated milking machines with yield logs per animal.

5. Poultry Chambers

5.1 Systems

Egg-laying Modules: Tiered nests with automated egg collection.

Feeding: Conveyor-based dispenser with intake monitoring.

Cleaning: UV disinfection + conveyor waste removal + air scrubbers.

6. Artificial Grazing Field (AGF)

Floor: Artificial turf with spring cushioning and embedded motion sensors.

UV-LED Arrays: Full-spectrum lighting for Vitamin D synthesis.

Exercise Units: Treadmills and “grazing walk loops” for muscle retention.

Simulation: Background visuals and sound systems for behavioral enrichment.

7. Aquaculture (Fish Farming)

RAS Tanks: Insulated, oxygenated tanks with biological + mechanical filtration.

Species: Tilapia, catfish, trout (high feed conversion ratio).

Water Sensors: Real-time temperature, ammonia, nitrate, and pH readings.

8. Feed Production & Storage

Sprouting Chambers: Rapid-cycle barley/alfalfa fodder trays (~7 days).

Fermentation Unit: Silage production from leftovers (low-oxygen storage).

Dry Feed Mill: Converts harvested crops to pellets.

9. Energy & Utilities

9.1 Power System

Primary: Solar arrays (surface or disguised rooftops).

Secondary: Wind turbines (if above-ground possible), biogas from animal waste.

Backup: Diesel generator with EMP-protected circuits.

Storage: 48V LiFePO₄ battery banks with BMS.

9.2 Water System

Sources: Rain capture, AWG (atmospheric water generators), recycled greywater.

Purification: RO filtration, UV sterilization, biological nutrient recovery.

Waste: Solid-liquid separators, anaerobic digesters, composters.

10. Control Architecture

Core Controller: Industrial PLC (e.g., Siemens S7) or edge AI module.

Remote Access: Encrypted satellite link or hardened fiber-optic uplink.

UI Interface: Touchscreen and mobile dashboard with real-time alerts.

AI Subsystems: Predictive crop modeling, livestock anomaly detection, feed balance optimization.

11. Technical Safety Systems

SystemFunctionBiosecurity DoorsPrevent zoonotic contaminationFire SuppressionInert gas or mist-based suppressionEMP ShieldingFaraday-caged critical electronicsAir FiltrationHEPA + UV + activated carbon triple-layer stackStructural SafetyShockproof, radiation-insulated enclosure

12. Scalability & Deployment Models

Deployment TypeArea (m²)Supported PopulationMicro-Bunker Module150–200 m²10–20 peopleMedium Shelter Farm500–800 m²100–200 peopleMilitary Compound Hub2,000+ m²500+ troops + staff

Conclusion

This secure indoor farming and livestock model allows continuous, efficient, and ethical food production in enclosed environments. Its design supports wartime sovereignty, disaster readiness, and strategic autonomy. With AI control, renewables, and scalable architecture, it ensures long-term nutritional security wherever surface agriculture fails.

Technical Article: Integrating Fruit Trees into Secure Indoor Farming Systems in Bunkers and Fortified Environments

By Ronen Kolton Yehuda (Messiah King RKY)

Founder | Villan | 1 Holdings & Investments

1. Objective

This article outlines the technical integration of fruit tree cultivation within secure indoor farming systems designed for subterranean shelters, military bases, and fortified installations. By incorporating dwarf and semi-dwarf fruit trees into sealed, AI-managed agricultural environments, the AgroShield system expands beyond vegetables and livestock to deliver critical nutritional, psychological, and oxygen-regulating benefits in enclosed spaces.

2. Role of Fruit Trees in Resilient Farming Systems

2.1 Nutritional Benefits

Provides essential vitamins: C, A, K, folate, potassium

Long-lasting harvests: Suitable for drying, canning, and jam production

Natural sugar source for energy and morale

2.2 Environmental and Psychological Benefits

Natural CO₂-oxygen exchange and humidity balancing

Color, aroma, and seasonal variation improve mental health in enclosed spaces

3. System Requirements for Indoor Tree Cultivation

3.1 Tree Selection Criteria

Dwarf or semi-dwarf cultivars (max height: 1.5–2.5 meters)

Fast-maturing, low-chill or no-chill varieties

Container or trellis-trained

SpeciesCultivar TypeIndoor SuitabilityCitrus (Lemon, Lime, Orange)Dwarf (e.g., Calamondin)HighFigCompact (e.g., Petite Negra)HighBananaMiniature (e.g., Dwarf Cavendish)HighAppleColumnar (e.g., Urban Garden™)Moderate (requires chill)PomegranateBush typeHigh

4. Indoor Orchard Design

4.1 Structural Requirements

Reinforced modular beds with root-depth of 40–70 cm

Overhead LED grow systems with 1.2–1.5 m light clearance

Integrated drainage trays and moisture sensors

Microclimate zoning via curtain walls or flexible partitions

4.2 Lighting and Photoperiod

Full-spectrum LED grow lights (3500K–4500K)

Supplemented with UV and IR channels for bloom support

12–14 hour photoperiods for flowering; adjustable via AI controller

Lighting intensity: ~250–400 µmol/m²/s at canopy

5. Environmental Control

5.1 Temperature & Humidity Zones

Citrus/Fig: 20–28°C | RH: 50–70%

Apple: Simulated chill cycle for dormancy (10°C for 6–8 weeks)

Banana: 24–30°C | RH: 60–80%

5.2 Pollination Systems

Manual pollination tools

AI microdrones or airflow fans for automated pollination

Optional indoor bee box modules in high-volume systems

6. Soil, Water, and Nutrient Management

6.1 Growth Medium

Soilless mixes: 70% coco coir + 30% perlite or custom blends

Aerated root zones with oxygen diffusers (for banana, fig)

6.2 Irrigation

Automated drip lines with fertigation injectors

pH control: Target range 5.8–6.5

NPK Optimization per species, managed via AI fertigation panel

6.3 Water Sources

Recycled greywater (post-treatment)

Atmospheric Water Generators (AWGs)

Rainwater if surface access is available

7. Integration with AgroShield Ecosystem

7.1 Closed-Loop Sustainability

Tree pruning waste → biomass digesters

Fallen fruit → animal feed or compost

Livestock waste → biofertilizer for trees

7.2 Food Processing

Fruit dehydration, canning, or vacuum-sealing

Onsite preservation unit powered by solar/biogas hybrid energy

8. AI & Automation

Growth monitoring via multispectral imaging

Sensor networks for soil moisture, trunk diameter, fruit size

AI-controlled lighting schedules and nutrient mix

Yield prediction and harvest alerts

9. Safety and Containment Systems

SystemFunctionFire SuppressionMist or inert gas, non-damaging to plant materialAir FiltrationHEPA + UV-C for pathogen controlQuarantine ZoneFor new tree arrivals or infected specimensEMP ShieldingProtect grow system electronics in conflict zones

10. Scalability and Applications

Facility TypeTree CountCrop Yield (est.)Micro-Bunker (200 m²)5–15 trees500–1,500 fruits/yrMedium Shelter (800 m²)40–100 trees10,000+ fruits/yrMilitary Hub (2000+ m²)250+ treesFull orchard ecosystem

11. Strategic Use Cases

LocationPurposeArctic or Desert BunkersVitamin preservation & psychological reliefNaval/Military SheltersFresh nutrient stock and morale supportUnderground CitiesLong-term fruit ecosystem for dense populationsSpace Stations or ColoniesClosed-loop, gravity-assisted tree farming modules

Conclusion

Integrating fruit trees into fortified indoor farming systems enhances the nutritional value, sustainability, and emotional resilience of enclosed life-support environments. With proper lighting, automation, and resource management, fruit trees can thrive alongside crops and animals — completing a resilient and sovereign food system in any secure shelter, bunker, or future smart colony.

Keywords: indoor fruit trees, secure agriculture, dwarf cultivars, bunker orchards, fortified food systems, hydroponic trees, AI farming, food security, agroshield, Villan infrastructure

Farming in Bunkers: Secure Indoor Agriculture for Crops, Animals, and Livestock in Times of Crisis

By Ronen Kolton Yehuda (Messiah King RKY)

As the world faces growing threats — war, natural disasters, supply chain collapse, and environmental instability — the need for food security has become more urgent than ever. One of the most practical and powerful solutions is the development of indoor farming systems designed for protected environments: bunkers, bomb shelters, military zones, and remote facilities.

These systems are not science fiction — they are real, scalable, and essential for survival. They combine indoor crop production, animal farming, and artificial fields for livestock movement, all protected from external dangers.

🌱 Growing Food Underground

Instead of relying on exposed fields vulnerable to weather and attacks, indoor systems use vertical farming, where vegetables, herbs, and fruits grow in stacked layers using hydroponic or aeroponic systems (no soil required). LED lights replace sunlight, while smart sensors monitor water, nutrients, and air quality.

This method can produce food 365 days a year, with minimal water, no pesticides, and full automation. It is ideal for small shelters or large underground facilities.

🐄 Raising Animals Indoors

Yes, even cows, sheep, goats, and chickens can be raised indoors — safely and ethically. Specially designed animal zones include:

Clean, climate-controlled pens

Soft flooring for joint health

Air filtering systems to keep the environment fresh

Automated milking machines and feeders

Biometric tracking for health and behavior

Animals are given enriched environments with movement areas, artificial grazing fields, and even simulated daylight using special UV-safe lights. These features prevent stress and maintain high-quality milk, meat, and eggs.

🐔 Poultry and Fish for Protein

Eggs and meat from poultry are easy to produce indoors. Chickens and ducks live in layered coops with automated systems for feeding, egg collection, and cleaning. Waste is recycled for fertilizer or energy.

Fish farming is another key feature. In clean, closed water tanks, fish like tilapia or trout grow with filtered water and smart feeding, supplying high-value protein with low space requirements.

🌾 Growing Feed and Artificial Grazing

To feed the animals, indoor farms include grain-sprouting rooms that produce fresh green fodder every week. These spaces require little water and no sunlight.

Meanwhile, animals like cows and goats can “walk” on artificial grazing fields — special indoor areas with turf flooring, daylight simulation, and exercise loops. This keeps their muscles active and supports natural behaviors even in tight spaces.

⚙️ Water, Energy, and Waste Systems

A secure indoor farm must be self-sufficient. That’s why these systems include:

Atmospheric water generators (pull water from air)

Solar, wind, and biogas energy systems

Recycling units that turn waste into fertilizer or electricity

Smart ventilation and temperature control

Everything is connected and managed with AI and automation, making the farm run efficiently without a large human team.

🏗️ Where and Why It Matters

This type of farming can be deployed in:

Military bases in conflict zones

Civilian bomb shelters

Underground hospitals or command centers

Remote research stations in deserts, polar regions, or mountains

Space preparation zones for future planetary habitats

It’s not just about war — it’s about resilience, survival, and sovereignty. In a world that’s becoming more fragile, these systems give governments, communities, and organizations a way to feed their people, even under the worst conditions.

🌍 A Future of Secure Food

At its heart, this concept is about more than farming. It’s about protecting life. Whether it's in times of peace or war, having the ability to grow food — vegetables, milk, eggs, fish, and meat — without relying on the outside world is one of the most powerful capabilities a nation or community can have.

We call this system: AgroShield — the shield of food, life, and security.

And in the age of uncertainty, it may become one of the most important infrastructures we build.