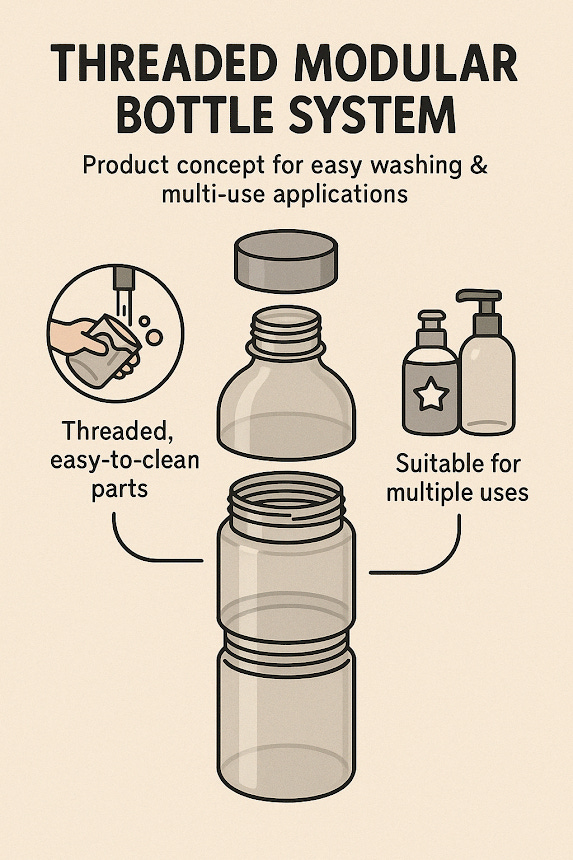

Threaded Modular Bottle System

Product Concept: Threaded Modular Bottle System for Easy Washing & Multi-Use Applications

Threaded Modular Bottle System

Product Concept: Easy Washing & Multi-Use Applications

By Ronen Kolton Yehuda (MKR: Messiah King RKY)

Overview

The Threaded Modular Bottle System is designed to make bottles and containers easier to clean, transport, assemble, and reuse.

It can be used for many everyday and professional products, including:

Sauce bottles

Baby bottles

Water and drink bottles

Soda-stream–style bottles

The core idea is simple:

Instead of one closed body, the bottle is divided into separate threaded sections that can be unscrewed, washed, and reassembled.

The same modular principle can also scale up to larger systems, such as solar water heater tanks and industrial containers, where easier transport and on-site assembly are a big advantage.

Key Features

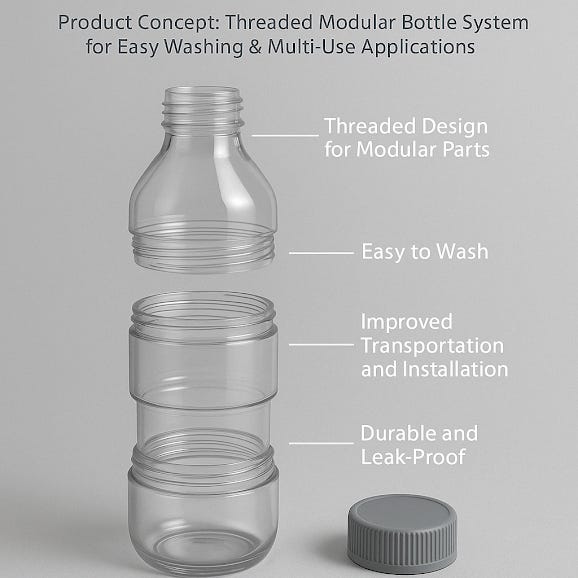

Threaded Design for Modular Parts

The bottle body is split into two or more sections, joined by threaded connections. Users can easily unscrew the parts, clean them, and screw them back together.

Easy to Wash

Because the bottle opens along its body, every inner surface becomes accessible. This is especially useful for baby bottles, sauces, and sugary drinks, where residue often stays in corners in traditional bottles.

Improved Transportation and Installation

For larger containers or systems (such as solar water heaters), the modular design allows the tank or bottle to be shipped in smaller pieces and assembled on-site. This reduces bulk, makes handling easier, and can lower logistics and installation costs.

Durable and Leak-Proof

The threaded joints are designed with seals and gaskets to prevent leaks and keep the bottle structurally strong, even after many open–close cycles.

Versatile, Cross-Category Design

Although developed first for bottles, the threaded modular concept can be adapted for:

Home and kitchen products

Healthcare containers

Industrial tanks and storage

Solar and energy-related systems

Eco-Friendly and Cost-Effective

The system supports reuse and repair: individual sections can be replaced instead of throwing away the entire bottle or tank. This reduces waste and can lower manufacturing, shipping, and replacement costs over time.

Potential Applications

Home and Kitchen Products

Sauce bottles, baby bottles, reusable water bottles, and drink containers

Easy disassembly for deep cleaning and long-term reuse

Attractive for brands and manufacturers focused on hygiene and sustainability

Industrial Use

Larger containers and tanks (for liquids, ingredients, or chemicals)

Tanks divided into manageable segments for assembly, disassembly, and transport

Reduced shipping costs and easier handling in narrow or difficult spaces

Healthcare

Baby bottles and feeding equipment that require frequent sterilization

Medical containers that must be cleaned or disinfected thoroughly

Threaded segmentation helps ensure a high hygiene standard

Solar Water Heaters and Large Tanks

Modular, threaded shells for solar water heater tanks

Easy transport of segments to roofs or remote sites

Simple on-site assembly for residential and commercial installations

Benefits

Convenience in Cleaning

The modular threaded design allows users to open the bottle along its body and clean each section directly. This is ideal for daily-use bottles that need regular washing, such as baby bottles, drink bottles, and refillable sauce containers.

Reduced Waste and Better Transport

Dividing large containers into smaller pieces:

Makes packaging more compact

Reduces the chance of damage during shipping

Allows more efficient use of storage and transport space

Easier Assembly and Installation

Whether it is a household bottle or a large solar tank, the threaded segments can be quickly screwed together, making installation simple and clear, with no need for special tools or welding.

Multi-Industry Applicability

The same basic threaded modular logic can be:

Small and light for consumer bottles

Strong and robust for industrial tanks and energy systems

This flexibility lets one design language serve many markets.

Eco-Friendly Approach

Fewer full products discarded when only one part is damaged

More efficient transport and packaging

Supports refillable, reusable, and longer-life products

Conclusion

The Threaded Modular Bottle System is a practical, modern answer to common problems in bottle and container design:

difficult cleaning, bulky transport, and complicated installation.

By using a modular screw-in structure, it offers:

Easier and more hygienic cleaning

Better logistics for both small bottles and large tanks

Simple assembly, maintenance, and part replacement

A flexible platform that can serve home, healthcare, industrial, and solar energy applications

By making cleaning and transport simpler, this system doesn’t just upgrade a bottle – it introduces a new class of modular containers that can be scaled, adapted, and reused across many industries.

Threaded Modular Bottle System – Technical Architecture and Design Principles

By Ronen Kolton Yehuda (MKR: Messiah King RKY)

1. Technical Overview

The Threaded Modular Bottle System is a structural and mechanical design for bottles and containers in which the main body is divided into multiple threaded segments instead of being a single fixed cylinder.

Each bottle is composed of:

A bottom body segment

One or more middle body segments (optional, to change volume)

A top body segment connected to the neck and closure (baby teat, sauce nozzle, soda cap, etc.)

The segments are joined using precision-molded threads, combined with gasket-based sealing, so that the assembled body behaves like a standard monolithic bottle, while still being fully openable for cleaning, inspection, and part replacement.

This technical architecture is designed to work across:

Baby bottles

Sauce and condiment bottles

Reusable and travel bottles

Soda / carbonated drink bottles (with reinforced sealing)

Small modular containers and, by extension, larger tank-like systems based on the same logic

2. System Architecture

2.1 Segment Geometry

Each bottle is defined by a nominal outer diameter and modular height, broken into segments:

Bottom segment

Slightly thicker base wall for impact resistance.

Optional small internal radius at the bottom to avoid residue traps.

Middle segment(s)

Straight or slightly curved cylindrical walls.

Can be produced in different heights to create multiple volume configurations.

Top segment

Transition from cylindrical body to neck geometry.

Interface for baby teat, screw cap, sports cap, pump head, sauce nozzle, or soda closure.

The segment mating faces are flat or slightly chamfered, with:

A threaded zone (for mechanical joining)

A sealing zone (for gasket/O-ring and lip interface)

The internal surfaces are designed to be smooth and continuous once assembled, minimizing flow disturbances and residue traps.

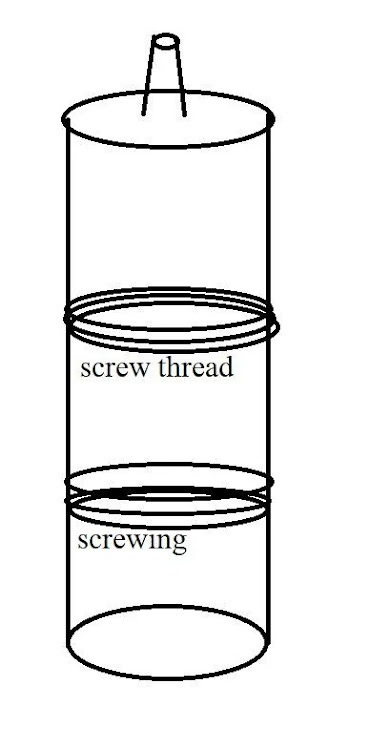

3. Threading and Sealing System

3.1 Thread Profiles

The system uses integrated body threads between segments:

Male thread on the top edge of a lower segment

Female thread on the bottom edge of the upper segment

Possible thread types (selected per product line):

Rounded or trapezoidal threads for smoother engagement and better fatigue resistance.

Tapered threads where additional sealing by compression is desired (e.g., soda / carbonated variant).

Multi-start threads for faster assembly (fewer turns from open to fully locked).

Thread pitch and depth are defined to:

Allow hand assembly without tools.

Provide a clear end-stop position when fully tightened.

Ensure stable axial clamping of the sealing element.

3.2 Sealing Stack-Up

To create a leak-proof joint, the design can combine:

O-ring or flat gasket placed in a dedicated groove on one of the segments.

Interlocking lip geometry near the inner diameter that closes as the thread is tightened.

In pressure-sensitive designs (e.g., carbonated drinks), use of:

Slight thread taper + O-ring

Defined compression range for the gasket

The sealing system is dimensioned for:

Typical beverage pressures (for soda variants)

Temperature ranges expected in:

Baby bottle sterilization (boiling / steam)

Dishwashing cycles

Normal refrigerator and ambient use

4. Materials and Compatibility

The Threaded Modular Bottle System is designed as a material-flexible platform. Depending on the use case, different materials can be specified:

4.1 Consumer and Baby Products

PP (Polypropylene)

Good heat resistance (dishwasher, sterilization).

Food-safe, low density, robust for daily handling.

Tritan™ or similar copolyesters

BPA-free, impact-resistant, transparent.

Suitable for premium baby, sports, or travel bottles.

HDPE / PET (for some drink or sauce containers)

Good barrier properties.

Must be balanced with thread precision and sealing performance.

4.2 Higher-Duty or Specialized Variants

Stainless steel (inner or full body) for robust, reusable bottles or small technical containers.

Glass (borosilicate) for high-temperature or premium applications, with plastic or metal threaded collars over-molded or fitted onto the glass segments.

Material selection is tied to:

Target temperature range

Required chemical resistance (e.g., sauces, acids, detergents)

Mechanical demands (drops, transport, pressure)

5. Functional Performance and Testing

To qualify a Threaded Modular Bottle System for real use, the following performance aspects are considered:

5.1 Mechanical Strength and Fatigue

Drop tests (filled and empty) from typical usage heights.

Cycle tests for opening/closing the threaded joints to evaluate thread wear.

Torsion tests on the joints to validate maximum hand tightening and misuse margins.

5.2 Leak and Pressure Resistance

Static leak tests with water under head pressure (bottle lying down, upside-down, on its side).

For soda variants:

Pressure tests at defined carbonation levels.

Temperature cycling (fridge to ambient) to check seal behavior.

5.3 Thermal and Hygiene Performance

Dishwasher cycles to confirm thread and gasket stability.

Boiling/steam sterilization for baby bottle variants.

Visual inspection and surface finish tests to ensure no micro-cavities where residue or bacteria can accumulate.

6. Manufacturing and Assembly

6.1 Production Methods

Most consumer segments are designed for injection molding:

Cavity design optimized for:

Uniform wall thickness

Precise thread reproduction

Good demolding without damaging fine features

Quality control focuses on:

Thread dimensions and tolerances

Run-out and roundness so segments align and seal properly

Gasket groove and sealing surfaces free of flash or defects

Metal or glass variants may involve:

Spun or drawn metal cylinders with welded or pressed threaded collars

Glass segments combined with over-molded or separate threaded rings

6.2 User Assembly Experience

The user flow is designed to be intuitive:

Align markers or reference lines on segments.

Engage threads and turn until a clear mechanical stop.

For baby and kitchen products, tightening by hand only must be sufficient to reach full sealing.

Torque targets and tactile feedback are considered so the user:

Feels when the joint is properly closed

Does not need excessive force

7. Variants and Functional Modules

The same core geometry can support multiple functional modules, for example:

Baby bottle middle ring with volume markings and anti-slip texture.

Sauce bottle segment with internal flow-shaping features.

Water bottle segment with integrated infuser basket or filter.

Travel bottle segments that can double as separate small containers when detached.

This allows:

A shared platform for different markets.

Future upgrades (new segments) that remain compatible with existing bottom and top parts.

8. Engineering Challenges and Design Responses

Key challenges include:

Thread wear over time

Solved through robust thread profiles, adequate wall thickness, and selecting materials with good fatigue properties.

Maintaining seal integrity after many cycles

Use of durable elastomers for gaskets.

Controlled compression range to avoid over-squeezing.

Balancing precision with cost

Defining tolerances that are tight enough for sealing but realistic for mass production.

Standardizing one or two thread families to reduce tooling complexity.

Cleaning behavior in real life

Internal geometry avoids sharp internal steps and crevices.

Segment lengths are chosen so that both manual cleaning and dishwasher washing are effective.

9. Summary

Technically, the Threaded Modular Bottle System is a structural and mechanical framework for bottles and containers that:

Uses threaded body segments instead of a single fixed cylinder.

Combines precise threads, gasket-based seals, and smooth internal geometry to behave like a standard bottle in use.

Enables deep, direct cleaning, easy part replacement, and adjustable volume configurations.

Can be scaled and adapted from baby and sauce bottles to soda bottles, travel bottles, and modular small containers, and conceptually extended to larger tank systems.

This technical architecture is what turns the concept from a simple idea (“a bottle that opens in the middle”) into a coherent, repeatable design platform that can support an entire product family across home, healthcare, and light industrial applications.

Revolutionizing Bottle Design: The Threaded Modular Bottle System for Easy Washing and Versatile Use

By Ronen Kolton Yehuda (MKR: Messiah King RKY)

In today’s world, bottles are everywhere: baby bottles, sauce bottles, reusable water bottles, soda bottles, and more. But most of them still share the same old problem — they are hard to clean properly, difficult to reuse for a long time, and often waste space in transport and storage.

The Threaded Modular Bottle System offers a new way to design bottles and containers: instead of one closed body with only a neck, the bottle is built from separate screw-together segments that can be opened, cleaned, replaced, and reconfigured.

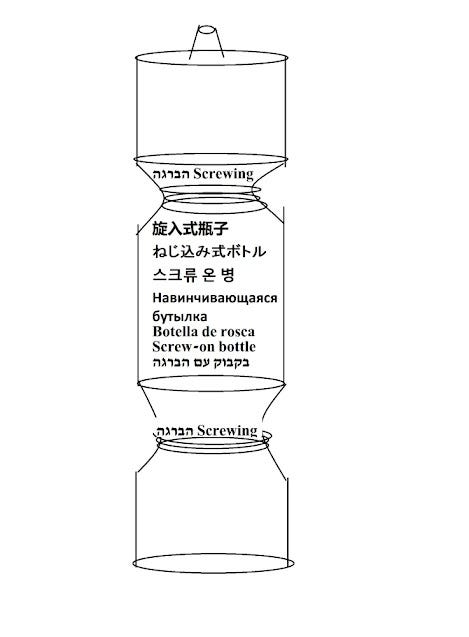

What Is the Threaded Modular Bottle System?

The Threaded Modular Bottle System is a bottle design where the main body is divided into two or more sections connected by threaded (screw-in) joints.

Instead of a single long cylinder, the bottle becomes a set of modular rings or segments that:

Screw together to form a strong, leak-proof bottle, and

Unscrew easily so the user can open the body and access every inner surface for cleaning or maintenance.

This concept is the same across the whole product family, and can be adapted for:

Baby bottles

Sauce bottles and condiments

Soda and carbonated drink bottles

Reusable water and travel bottles

Larger containers and even tank-like systems (for example, solar water heaters)

How the System Works

1. Modular Segments

Each bottle is built from two or three main body segments, plus the neck and cap:

Bottom segment

One or more middle segments

Top segment that connects to the neck or feeding/dispensing head

Each segment has male threads on one side and female threads on the other, so segments can be combined like a chain.

2. Threaded Joints and Sealing

At each junction between segments, the design integrates:

Threads for mechanical strength and alignment

Gaskets or O-rings for watertight and airtight sealing

Optional interlocking lips to further block leaks

Once assembled, the bottle behaves like a conventional container in daily use — but it can be opened along its length at any time.

3. Materials and Versions

The system can be implemented in different materials according to the use case:

Food-safe plastics (for baby bottles, kitchen bottles, water bottles)

Tough, transparent plastics (for reusable bottles and sports bottles)

Metals and stronger materials (for larger or industrial containers)

Glass options (for premium or high-temperature bottles)

Home and Kitchen: Baby Bottles, Sauce Bottles, Drink Bottles

In the home, the Threaded Modular Bottle System solves one of the most common frustrations: cleaning the inside properly.

Baby bottles

The bottle can be opened into two or three rings, so every surface can be washed and sterilized easily.

Parents can see that nothing is left stuck in corners or at the bottom.

The same bottle system can be adjusted in size by adding or removing a middle segment.

Sauce bottles and condiments

Sauces like ketchup, tahini, chocolate syrup, and dressings often leave sticky residue inside.

With a modular sauce bottle, the user unscrews the body, wipes all inner walls, and reassembles it — making refillable and long-life sauce bottles practical.

Soda and beverage bottles

Stronger threaded joints and seals can be used for carbonated drinks.

Modular body segments allow better cleaning of sugary residues and easier customization of bottle volume.

Reusable and travel bottles

Bottles can be opened fully to remove odors and deposits.

Segments can be swapped, nested, or packed separately, making them space-efficient for travel.

Special middle segments can include filters, infusers, or insulated sections.

Healthcare and Hygiene Applications

In healthcare and baby care, hygiene is critical. The modular design supports:

Feeding bottles and cups that must be sterilized frequently

Containers for special liquids or formulas that cannot tolerate residue

Medical-grade storage bottles where disassembly for cleaning is important

By allowing each part to be removed and cleaned directly, the system helps maintain a higher hygiene standard than classic one-piece bodies.

Industrial and Large-Scale Uses

The same logic can scale up beyond simple bottles. The Threaded Modular Bottle System can inspire:

Modular storage containers for chemicals or liquids

Sectioned tanks that are easier to ship in parts and assemble on-site

Solar water heater tanks constructed from screw-together cylinder segments

For example, a solar water heater tank can be divided into three or more threaded shells. Each shell is lighter and easier to carry through stairwells or up to rooftops. At the destination, installers simply screw the sections together, seal them, and connect to the system. This can reduce transport volume, simplify logistics, and lower installation effort.

Key Benefits of the Threaded Modular Bottle System

Convenience and Time-Saving

Bottles can be opened along the body, not just at the neck.

Users can clean quickly and thoroughly, without special brushes.

Enhanced Hygiene

No hidden corners: every inner surface becomes accessible.

Better suited for baby bottles, healthcare containers, and reusable bottles that must stay very clean.

Compact and Efficient Transport

When disassembled, segments can be packed more compactly.

Large containers and tanks can be shipped in smaller pieces, reducing shipping volume and risk of damage.

Versatile Applications

The same concept works for personal, kitchen, healthcare, industrial, and renewable energy products.

Brands can build entire product families on one modular thread standard.

Cost-Efficient and Sustainable

Individual sections can be replaced instead of discarding the entire bottle.

Improved reusability and better cleaning support longer product lifetimes.

More efficient transport and less packaging can reduce environmental impact.

Technical Perspective and Design Considerations

From a technical point of view, the system focuses on:

Thread geometry that aligns segments precisely and resists wear over many open/close cycles.

Sealing systems (O-rings, lips, tapered threads) to handle different pressures and temperatures.

Material selection to match the bottle’s purpose:

Plastics for everyday bottles

Metals or stronger materials for tanks and pressurized systems

Glass or special composites where heat or chemicals require it

Engineering teams must also balance manufacturing complexity and cost, since precise threading and sealing demand high-quality production. However, once the core standard is established, many products can reuse the same geometry.

Conclusion

The Threaded Modular Bottle System offers a fresh, practical way to rethink how bottles and containers are made and used. By turning the bottle into a set of threaded, modular body segments, it makes deep cleaning easier, extends product life, and improves transport and storage.

From baby bottles and sauces in the kitchen, through reusable water and soda bottles, to larger containers and solar water heater tanks, the same concept can be adapted and scaled. It transforms bottles from sealed, hard-to-clean objects into modular tools that can be opened, maintained, customized, and reused more intelligently.

As a product family and design language, the Threaded Modular Bottle System has the potential to change how we think about container design, cleanliness, and logistics across both consumer and industrial markets.

Threaded Modular Bottle System – One Bottle Family for Baby Formula, Sauces, Soda and More

In most kitchens and homes, bottles are still designed the same way they were decades ago: one fixed body, one cap, and a narrow neck that is difficult to reach and properly clean. Parents struggle to scrub baby bottles, sauce bottles become sticky and stained, and reusable drink bottles collect odors and residue over time.

The Threaded Modular Bottle System starts from a different assumption:

the bottle itself should be modular and openable along its body, not just at the top.

Instead of being one closed cylinder, the bottle is built from two or three threaded body segments that screw together into a single, strong container. When needed, the segments are unscrewed, cleaned, reorganized or replaced – then reassembled in seconds.

This is a unique, named product family that can be applied to baby bottles, sauce bottles, soda bottles, travel bottles and more, all using the same core idea.

1. Core Idea: A Bottle Built from Threaded Rings

In a typical bottle, you only have access through the neck. In the Threaded Modular Bottle System:

The main body of the bottle is divided into:

A bottom segment

One or more middle segments

A top segment that connects to the neck and cap

Each segment has precision threads:

Male threads on one side

Female threads on the other

When the segments are screwed together, gaskets and sealing lips create a leak-proof body that behaves like a normal bottle in use – but can be opened along the body when you want to.

This structure is the same “language” across all product types:

baby bottles, sauce bottles, soda bottles, and other containers can share the same modular philosophy, adapted in size, material and details.

2. How It Works

Assembly

Choose the segments you need (for example, 3 small sections for a compact bottle, or 2 long sections for a tall bottle).

Align the threads, insert any gasket that belongs in that joint, and screw the segments together until the stop position.

Use

Once assembled, the bottle feels and works like any regular bottle.

It can be shaken, stored in the fridge, carried in a bag, or mounted on a baby bottle teat, sauce nozzle, or soda cap.

Disassembly & Cleaning

When it is time to clean, simply unscrew the body segments.

Every internal surface is fully accessible – no hidden corners, no narrow sections that a sponge can’t reach.

Wash, dry, and reassemble. If one part wears out, only that single segment can be replaced.

3. Baby Bottles: Deep Cleaning and Easy Handling

Baby bottles demand the highest hygiene standards. Traditional designs often leave:

Milk residue in corners

Scratches from brushes where bacteria can hide

Narrow bodies that are hard to reach

With the Threaded Modular Bottle System for baby bottles:

The bottle body can be separated into two or three rings, so each ring can be washed and sterilized thoroughly.

Parents can see and feel that every surface is clean – no guessing.

Different segment sizes allow:

Smaller volume configuration for newborns

Larger configuration for older babies, using the same neck and teat connection

Optional design features:

Textured outer surfaces for better grip when holding and feeding

Color-coded middle segments to mark different volumes or types of liquid (milk, water, formula mix)

4. Sauce Bottles: No More Sticky, Permanent Residue

Sauce bottles (ketchup, tahini, chocolate syrup, dressing) tend to become:

Sticky on the outside

Crusted on the inside around the shoulder and cap

Almost impossible to fully clean, so they are often thrown away

The Threaded Modular Bottle System for sauces offers:

Full-body access: unscrew the middle segment and clean viscous residue easily.

Better management of thick sauces: internal geometry can be shaped for smoother flow since cleaning is no longer a problem.

Possibility of interchangeable segments:

One short middle ring for compact bottles

One long middle ring for family-size bottles, using the same bottom and top parts

For refillable sauces (restaurant use, zero-waste stores, home refills), this design makes it practical to deep-clean and reuse containers instead of discarding them.

5. Soda & Carbonated Drink Bottles: Modular, Yet Pressure-Aware

Carbonated drinks add one more challenge: internal pressure.

In a Threaded Modular Bottle System for soda bottles:

The threaded joints and gaskets are engineered to withstand typical carbonation pressures.

The body segments are shaped to distribute mechanical load evenly around the cylinder.

Optional reinforced middle segment can be used for highly carbonated drinks, while the same neck and base parts can work across different volume options.

Advantages:

Easier cleaning for sticky, sugary residues.

Customizable bottle height and capacity by changing the combination of segments.

Potential integration of special middle rings (for example, a ring that includes a sleeve for cooling gel or a built-in handle).

6. Everyday Water, Travel and Multi-Use Bottles

Beyond baby, sauce and soda, the same system can be extended to many other everyday bottles:

Reusable water bottles

Easier to clean than long, narrow one-piece designs

Possibility to add a filter segment or an infuser segment for fruit and herbs

Travel bottles

Detachable segments that can be used as separate small containers during travel

Stackable storage: segments can be nested or rearranged for compact packing

Special-purpose bottles

Sports bottles with a middle grip ring

Thermally-insulated segments for hot drinks (with double-walled middle sections)

The modular body becomes a platform: the same thread standard can support many specialized features.

7. Design Benefits for Users and Manufacturers

For Users

Real cleaning: no “mystery zone” inside the bottle. Every surface is accessible.

Longer product life: if one part is damaged, just replace that segment.

Customization: adjust volume and function by choosing different segments.

Space saving: separate segments for compact storage when not in use.

For Manufacturers & Brands

One unified thread standard can support multiple product lines: baby, kitchen, sports, travel.

Easier to create families of products with shared parts, colors, and accessories.

Opportunity for upgrade paths – offering optional new middle rings (filter, insulated, decorative) that match existing bottles.

8. Extending the Same Logic to Larger Containers

Although the Threaded Modular Bottle System is designed first for bottles, the same principle can be scaled up:

Larger containers for home or light industrial use

Modular segments for compact transport and on-site assembly

Easier internal inspection and cleaning, even in large volumes

This shows that the concept is not just a small tweak, but a structural approach to how containers of many sizes can be built and serviced.

9. Conclusion

The Threaded Modular Bottle System reimagines the bottle as a set of cooperating body segments, not a sealed cylinder that is hard to reach and hard to clean. By dividing the body into threaded rings, the system delivers:

Deep hygiene for baby bottles

Clean, reusable sauce bottles with no permanent residue

Pressure-aware, modular soda bottles

Flexible, easy-to-pack everyday and travel bottles

All of this comes from one central idea:

a bottle that opens along its body, not just at the top.

This unique modular structure creates a new generation of bottles that are easier to live with, easier to wash, longer-lasting, and adaptable to many different uses and industries.

Legal & Collaboration Notice

The Threaded Modular Bottle System — including its threaded, screw-in structural design; modular bottle segmentation; sealing systems; gasket integration; and cross-industry adaptation for household, healthcare, and industrial applications (including solar water heaters) — is an original invention and publication by Ronen Kolton Yehuda (MKR: Messiah King RKY).

This innovation — encompassing its mechanical threading architecture, sealing and material system, modular transport design, and multi-sector adaptability — was first authored and publicly released to establish intellectual ownership and authorship rights.

All associated technical descriptions, mechanical drawings, design specifications, process outlines, and product texts are part of the inventor’s intellectual property.

Unauthorized reproduction, industrial adaptation, or commercial use without written consent is strictly prohibited.

The Threaded Modular Bottle System introduces a scalable thread-based modular connection for bottles, containers, and tanks of all sizes — enabling easy washing, improved hygiene, efficient transport, and simplified assembly. Its design extends from small consumer bottles (such as baby bottles, sauce bottles, and drink containers) to large industrial applications such as solar water heaters, chemical containers, and modular storage systems, establishing a new class of sustainable, reusable, and transport-efficient product architecture.

I welcome ethical collaboration, licensing discussions, manufacturing partnerships, and investment inquiries for the responsible development and industrial implementation of this innovation.

— Ronen Kolton Yehuda (MKR: Messiah King RKY)

Here’s a simple, clear section you can paste into your article for the Threaded Modular Bottle System 👇

Simple Patent & Production Note – Threaded Modular Bottle System (with ChatGPT)

For this bottle concept, I asked OpenAI’s ChatGPT (model GPT-5.1 Thinking) to help me look at publicly available information about modular / refillable / threaded / stackable bottles on the web. This is not a full legal patent search, just an AI-assisted check to understand the situation.

1. What already exists (in simple words)

From this check, it is clear that:

There are already many modular bottles and products in the world – for example bottles that let you change the tops, extend the volume with extra pieces, or connect bottles together.

There are also modular or “interconnecting” bottles and closures in patents, plus bottle systems that use special threaded or interlocking parts.

So the general idea of “a modular / special bottle” is not new. It has a lot of prior art and some active patents.

2. What seems different in the Threaded Modular Bottle System

In this limited AI review, I did not see a patent or product that clearly describes exactly what I call the Threaded Modular Bottle System, meaning for example:

A bottle whose main body is designed as two or three structural body rings (segments) along the height,

These segments are joined by threaded connections so the bottle can be taken apart, carried or stored in parts, cleaned or reconfigured, and then screwed back together to behave like one normal bottle,

All within one modular family that can share the same threaded interfaces across different bottle sizes or variants.

Single ideas like “threaded joints”, “refillable bottle”, or “modular add-ons” already exist, but this exact combination and workflow appears to be your own specific implementation, as far as this quick check can see.

3. Is it patentable?

Because there is so much prior art in bottles, nobody can promise a patent in advance. But based on this AI review:

The broad concept “modular bottle” is already known.

Your specific way of doing it (threaded body segments, how they join, how the system is used) might still be patentable,

If a patent application focuses on the exact technical details that make your design special (shape of the threads, sealing, how segments align, how users assemble and use it, etc.).

Only a patent attorney or patent agent can tell you clearly “yes, this is patentable” or “no, it’s too close to existing patents,” after a full professional search.

4. Can I still go ahead and produce it?

Yes – in general:

You are allowed to design and produce your own bottle system, even if you never get a patent.

Expired patents are not a problem – they only show what was done before.

The main thing is not to copy a still-active patent or a protected design too closely (for example, not copying a current product 1:1).

From this limited AI check, there is no obvious patent that clearly blocks you from making your own version of a threaded modular bottle system, especially if you:

Use your own geometry and look,

Do not copy an existing commercial modular bottle layout or design exactly, and

Adjust details if a human patent professional later finds a close active patent.

For small-scale or early prototypes, it is usually reasonable to “go for it” and build and test your idea.

For large investments, mass production or big marketing, you should talk to a qualified IP / patent lawyer to get a proper opinion about patentability and freedom to operate in your target countries.

5. Role of ChatGPT

This note was written with the help of ChatGPT, which:

Looked at public web information about modular and threaded bottles,

Helped compare that with my concept, and

Helped write this explanation in clear language.

It is only an AI-assisted information summary – not official legal advice and not a patent decision.

— Ronen Kolton Yehuda (MKR: Messiah King RKY)

Links

1: Holdings & Investments — Ronen Kolton Yehuda

Villan — The V That Challenges Giants

Fast Food Inc. — Ronen Kolton Yehuda

SmartSole/ Smart Unit for Soles/Shoes OS V1 of Villan

Flight-Ready Intelligence: Smart Glasses, Helmets, and Shoes in Advanced Aviation Suits

Smart AI-Powered Fan with Camera Tracking and Voice Interaction (Wheels version too)

The Smart Hat: A Wearable Computing Hub for the Future

Flying Kick Scooters & Skateboards Powered by Propellers — The Future of Urban Mobility

Hover Mobility: The Future of Scooters and Skateboards — Regular and Hybrid Designs

Elevatus House: The Flying Safe Haven of the Future

SkyHouse: The Flying Smart House That Escapes the Inventions of the Future

Flying Hotels, Flying Malls, and Flying Houses: Hybrid-Energy Airborne Infrastructure by Villan

The Flying Facility & Surface Unit: Self-Sustaining Airborne Infrastructure

Air/ Flying Bases & Stations, surfaces: The Future of Airborne Infrastructure

Villan Hybrid Digital Tournaments and Olympic Games

The Use of Digital Avatars for Experimenting on Human Biology and Living Nature

A Digital Board Game Platform — Ronen Kolton Yehuda

V1 OS by Villan — Ronen Kolton Yehuda

Tiny Mobile PC & Tiny Resilient Mobile PC

Tiny Resilient Mobile PC — Ronen Kolton Yehuda

FoldBook — The Foldable Future of Computing

External Virtual Keyboard for Desktops

SmartHealth System by Villan — Ronen Kolton Yehuda

The Smart Diaper — Ronen Kolton Yehuda

Hybrid Human-Robot Agent Systems: Exoskeletal Technologies for Security, Rescue, and Human Care

Villan Smart Irrigation System — Ronen Kolton Yehuda

The Smart-Screen: The Future of Wearable Technology

Smart Ankle & Smart Insole: A New Era in Footwear Technology

Modular Smart Sole Unit — Ronen Kolton Yehuda

Free-Moving Submarine Mobility System: Public, Private, and Cargo Transportation

Free-Moving Submarine Train for Passengers and Cargo

Free-Moving Submarine Cable Cars — Ronen Kolton Yehuda

Hybrid Security Patrol Vehicle: Drive, Dive, Fly, Defend

Hybrid Patrol System (HPS) for All Vehicle Types

The Flying & Diving Trains of Peace, Hope, and Prosperity

Flying Bus — Ronen Kolton Yehuda

Flying train, flying cargo train, flying floating train

Flying Cable-car Service Cabins — Ronen Kolton Yehuda

Smart Map — Ronen Kolton Yehuda

The Hybrid AR/VR Glasses with LCD Eye Display

Villan SmartSole OS V1 — Ronen Kolton Yehuda

Autonomous Selling Service Carts: A New Frontier in Mobile Retail and Hospitality

AI for Justice — Ronen Kolton Yehuda

The Good/Naive AI — Ronen Kolton Yehuda

A Modular System for Easy Screen and Keyboard Replacements for Laptops

The Laptop with SIM Card for Internet and Calls

AI Robotic Studio for Video Creating & Broadcasting

AI-Powered Medical Screening: The Future of Health Security and Preventive Diagnostics

Artificial Intelligence for War, Operations, and Tactical Combat Management

The Retailer Digital Trade Platform

The Integration of DV Language with AI: From Teaching Instruments to Creative Machines 🎶🤖AI-Powered Pollination Robots: The Future of Smart Agriculture

Hybrid Robots: The Fusion of Manual Expertise and Autonomous Intelligence

Soft Olive Oil: A New Kind of Olive Oil from Preserved Table Olives

Threaded Modular Water Heater - Ronen Kolton Yehuda

Fully AI-Automated Plant Agriculture System — Vertical Plant Growth on Multiple Levels

Meet Your New Social Media Manager: AI

Autonomous Stair-Climbing Lift: A New Era in Vertical Mobility

Full-Cover Soil Shading: A Smart Way to Beat the Heat and Stop Weeds🌾 Full-Cover Soil Shading Using Real Grass Cover

Targeted Soil Shading: Scalable Ground Shade Solutions Around Tree Trunks and Plant StemsAI for Patents

The Brain as the Key to Biological Immortality: Telomere Preservation Through Neural Implants

Office+ by Villan — Ronen Kolton Yehuda

Propeller Flight Frame System — AI-Powered Aerial Transport for Heavy Objects

AI for Scouting: Smart Talent Discovery Engine

The +device by Villan — Ronen Kolton Yehuda

Vegetable & Potato Stackable Chips: A New Take on a Crunchy Classic

M&Ns — Mixed & Noble Bites — Ronen Kolton Yehuda

Cocoa Fruit/ Pod Bites — Mini Chocolate Pods for Everyone 🍫🌈

Color Chocolate Bars — The New Palette of Taste and Imagination 🍫Arbitration by app — Ronen Kolton Yehuda

WaTH App: Revolutionizing Real-Time Communication with Walkie-Talkie Technology

Autonomous and Manual Hybrid Stretcher: Ground or Hover Mobility

Push-to-Treat Irrigation Gun: Dual-Use Innovation for Plant Care and Cleaning

Journalist AI for Today: Transforming News in Real Time

AI for End-to-End Product & Service Development

Music Theory with DV Language 📘 By Ronen Kolton Yehuda (MKR: Messiah King RKY) with the assistance of AIAI-Enhanced Skewers for Shawarma: A New Era of Intelligent Grilling

AI Digital/RPA Warehouse Supermarket: Revolutionizing Grocery Shopping

Smart Autonomous Carts and Suitcases

Autonomous Industrial Cart — Ronen Kolton Yehuda

Hybrid Autonomous Forklift with Remote Control and Manual Driving Mode

How AI Assistants Are Transforming Sports Management

AI Assistants in Judging Sports: Enhancing Fairness, Precision, and Transparency

NameFinder AI — Ronen Kolton Yehuda

AI on Fabric: Autonomous Design Systems for On-Demand Fashion

The Rise of AI Lie Detection: How Machines Are Learning to Spot the Truth

Accommodation App & Shavasana Rest Services

Autonomous and Manual Hybrid Stretcher: Ground or Hover Mobility

Sprout: A Global Initiative for Biodiversity and Food Security

FireShield Flora: Protective Spray for Wildfire Prevention in Forest Ecosystems

Perfumed Bidet Spray for Post-Toilet Hygiene: A Modern Alternative🤖 Autonomous Weed Removal Robot: Precision Weed Control for Farms and Gardens

Blink ;).. — Ronen Kolton Yehuda🛍️ AR/VR 3D Product Experience System

AR/VR Experience with Smartphones, Tablets, and More

AR/VR Simulators and Trainers: Transforming the Future of Skill Development

AR/VR Hybrid Smart Glasses: A Dual-Purpose Revolution

The Future of Cinema: Immersive VR/AR and Beyond

Solar / Sun Sauna: A Smart, Sustainable Revolution in Heat TherapySmart Shoes: Revolutionizing the Future of Footwear and Technology

The Future of Smart Wearables: A New Era of Connected Technology

DVLCO — DV Language Composer Orchestra (Demo v1)The DV Language Composer Family — Ronen Kolton Yehuda

The DV Language: David’s Violin Language

The DV Language 📜 — Ronen Kolton Yehuda

Preventing Food Waste Through Sustainable Processing of Near-Expired Products

Capturing and Treating River Water Before It’s Wasted to the Sea/ Ocean

Can Electricity Accelerate Plant Growth?

Turning Air into Ice — and Freezing Mountains Too: A Vision for Climate-Resilient Water Systems

Growing Icebergs & Iceberg Freezing Platforms

Restoring Earth: A Global Plan for Climate Healing

Microbial-Enhanced Plant Nutrition: Symbiotic Pathways to Smarter Agriculture

Push-to-Treat Irrigation Gun: A Smart Hose-End Tool for Nutrients, Microbes, and Soil Health

♻️ Clean Steps Composting Tools: Smart Compost Solutions for Homes, Gardens, Balconies & Businesses

The Thought Police: Quantum Justice and the Ethics of Mind Transparency

Social: Social Media — Ronen Kolton Yehuda

The Frozen Pizza Array System for Pizzerias

International Falafel Standards Organization (IFSO)Pita Reinvented: Mixing Flours, Grains, and Legumes for the Next Generation of Bread

Naïve Marketing — Ronen Kolton Yehuda

Beyond Semolina: Reinventing Couscous/ Instant Couscous with Grains and Legumes

Reinventing Rice Paper: Exploring Flour Combinations from Grains and Legumes

Title: Whole-Protein Pasta Blends: From Penne to Ptitim

High-Protein Multigrain Crackers: Crisp, Clean, and Packed with Power

High-Protein Multigrain Stackable Chips/ Crisps: A Smarter Twist on Pringles

High-Protein Multigrain Nacho Snack: A Nutritious Crunch You Can Feel Good About

AI that performs tasks for users directly within the OS

Healing the Planet: Aquifers, Forests, Lakes, and Ice — A Global Climate Restoration Architecture

Authored by: Ronen Kolton Yehuda (MKR: Messiah King RKY)

Check out my blogs:

Substack: ronenkoltonyehuda.substack.com

Blogger: ronenkoltonyehuda.blogspot.com

Medium: medium.com/@ronenkoltonyehuda

Authored by: Ronen Kolton Yehuda (MKR: Messiah King RKY)

Check out my blogs:

Substack: ronenkoltonyehuda.substack.com

Blogger: ronenkoltonyehuda.blogspot.com

Medium: medium.com/@ronenkoltonyehuda